Industrial fermentation — the large-scale use of microorganisms to create valuable products — supports industries from pharmaceuticals to food production.

To prepare the next generation of scientists and strengthen the biotech workforce, the Institute for Advanced Learning and Research (IALR) hosted the 2026 VT-IALR Industrial Fermentation Workshop on Jan. 12-16, 2026.

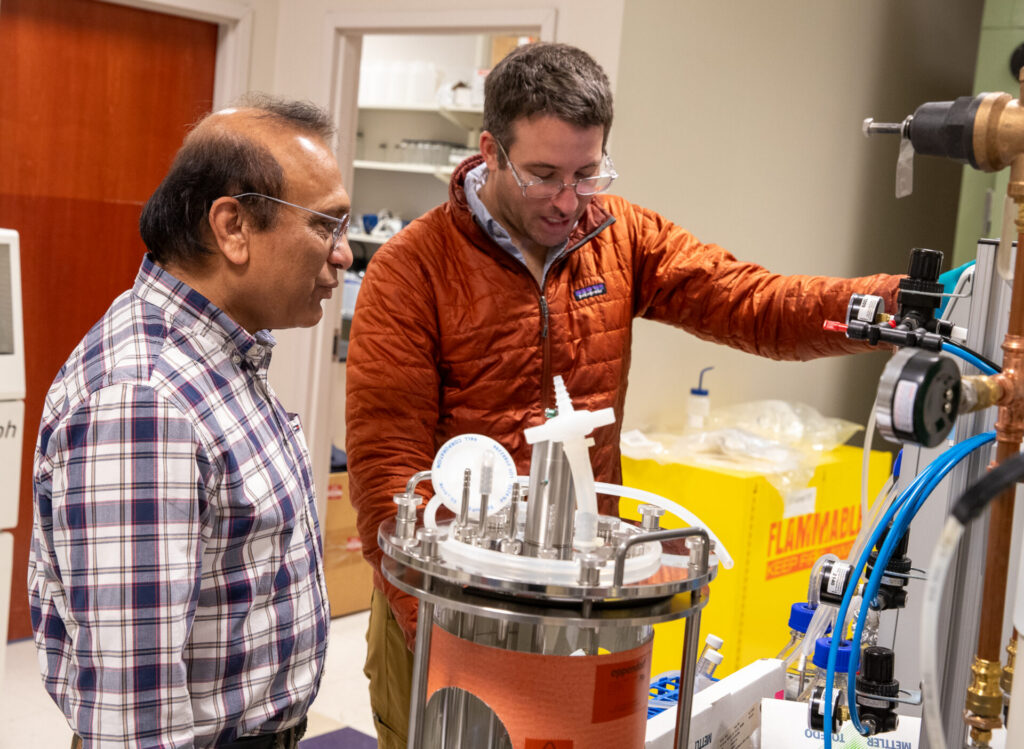

Co-taught by Dr. Scott Lowman, vice president of Applied Research at IALR, Dr. Biswarup Mukhopadhyay, professor in Virginia Tech’s Department of Biochemistry, and industry experts, the five-day, hands-on workshop served participants ranging from undergraduate students to faculty and working professionals seeking to broaden their skills.

The result was a blend of classroom instruction, laboratory experiments and real-world insights into scaling microbial processes.

“We’re so thrilled to host the workshop here at IALR. It’s an excellent opportunity for us to bring academic experts and industry together for a hands-on, fast-paced introduction to industrial fermentation,” said Lowman.

Interdisciplinary Focus on Scale-Up

Fermentation requires alignment among microbiology, chemical engineering, and related disciplines to scale a process from the lab to commercial levels successfully. Participants explored how smaller experiments translate to larger bioreactors and industrial processes.

“Development of a bioprocess technology occurs in a lab mostly using tools such as Petri plates or small flasks. When scaled up for manufacturing in a bioreactor, often it doesn’t work the same way one established in the lab or the cost becomes prohibitive for commercialization,” said Mukhopadhyay. “Part of this workshop is about learning how to design research early on so the process will translate well to a larger bioreactor. Our focus is on an intensive/immersion approach to bring up the participants up to speed and to inspire a career choice for folks at several levels within the discipline.”

Dr. Biswarup Mukhopadhyay (left) of Virginia Tech and Dr. Zachary Baer of IFF were two of the ten instructors of the week-long industrial fermentation workshop.

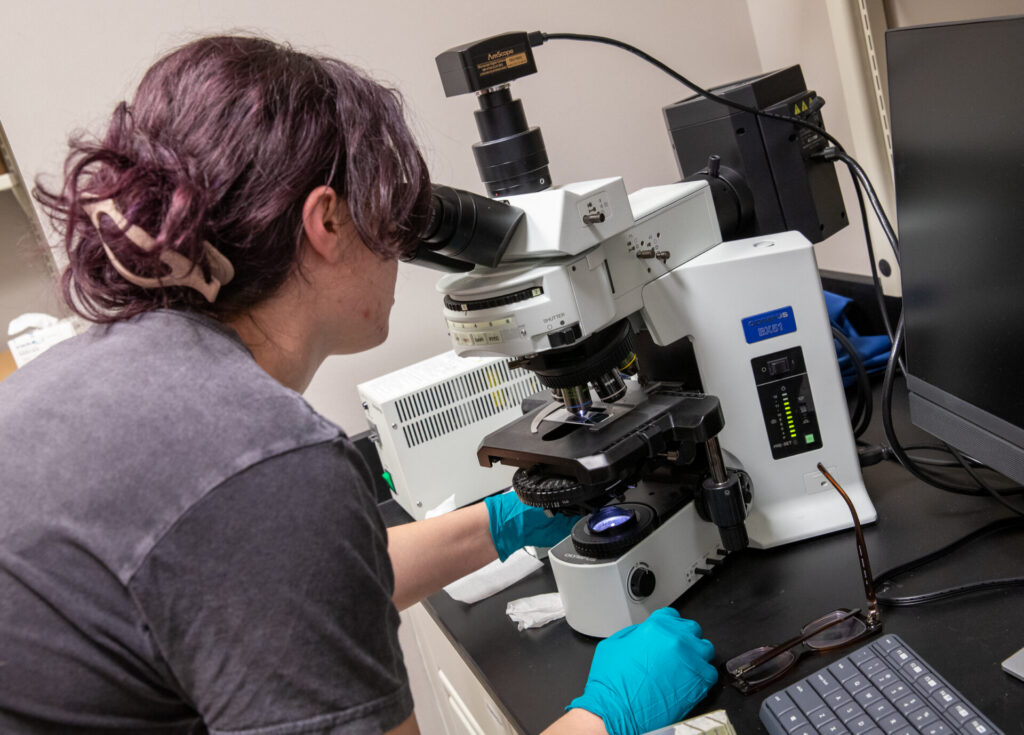

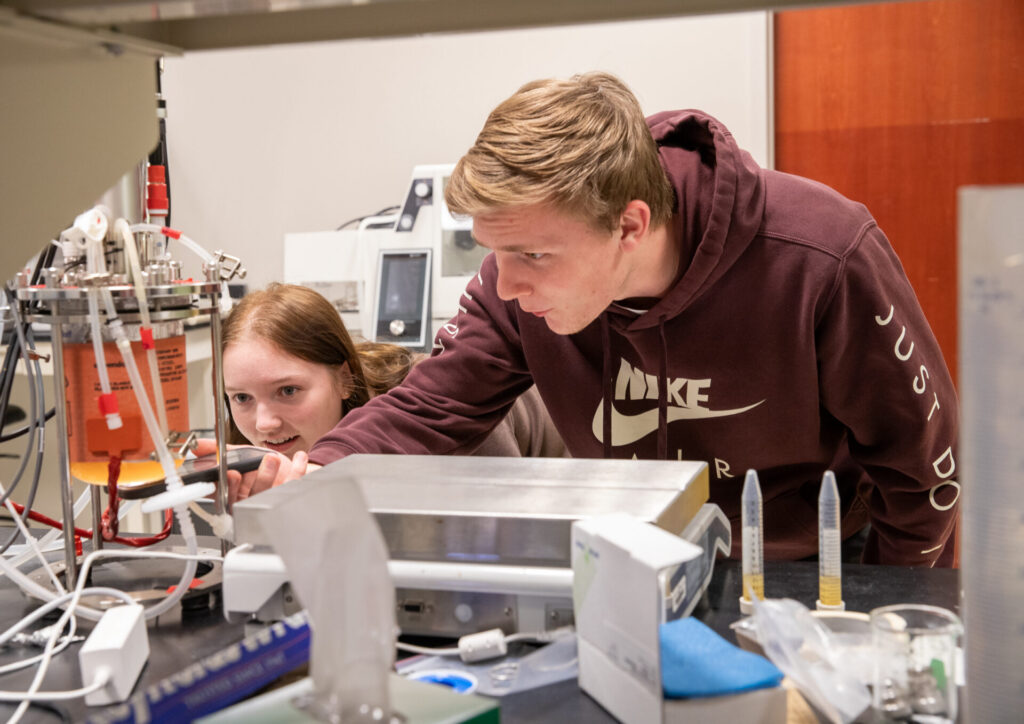

Hands-on learning with advanced equipment

Participants spent significant time operating bench-scale bioreactors, adjusting temperatures, pH and feed through automation, and collecting real time data. Bioreactor manufacturers, Distek Inc. and Eppendorf North America, and analytical instrument companies, Xylem Inc. and Hamilton Company, provided systems that allowed participants to apply their lecture material immediately.

Program instructors included representatives from Eppendorf Americas, International Flavors & Fragrances (IFF), Distek, Inc., XylemAnalytics North America, IALR, Virginia Tech and Hamilton Company.

Many participants said the hands-on experience made the difference.

“My favorite part was that I got this hands-on experience with a bioreactor. I loved the discussion part of this workshop, and I loved hearing the industrial perspective,” said Dr. Gönül Schara, California State University, Stanislaus. “I can easily say this was the best workshop I’ve ever attended. It was very intense, it was packed and I learned a lot.”

Participant Perspectives

Attendees included Virginia Tech undergraduates and graduate students, Virginia Western Community College faculty, Cal State faculty and others exploring how fermentation applies to their teaching or research.

Dr. Kristylea J. Ojeda, a professor of Biotechnology at Virginia Western Community College, said the hands-on experience was invaluable.

“The hands-on portion of the class — being able to work with the reactor, set it up, monitor it and take it apart — was incredibly valuable,” Ojeda said. “One of the big positive takeaways is having new connections and people to contact as we build out our curriculum.”

Dr. Heather Lindberg, a biology professor with Virginia Western, highlighted the relevance to workforce needs.

“I loved seeing the fermenters and seeing what we’re going to be training our students on and being able to speak with the professionals who have worked with this equipment before,” Lindberg said. “I feel much more equipped to teach. This will help ensure students are immediately valuable in the field.”

From the Virginia Tech graduate cohort, Lois Kyei said the workshop directly bridges lab work with industry methods.

“This workshop was immersive,” Kyei said. “In our lab, we grow microbes for discovering novel biomolecules, but this workshop was really insightful. I’ll be able to take things we learned here and apply them to growing strains in our labs.”

Fellow Chemistry Ph.D. student Karla Piedl emphasized how the program connected academic practices to realities of scale-up.

“I was really interested in understanding how we can take what we do in the lab and translate that to an industrial scale,” Piedl said. “The workshop was really hands-on. I’m excited to take some of the information given during this workshop and apply it to what we do in the lab.”

Undergraduates said the experience clarified both concepts and career pathways.

Virginia Tech biochemistry senior Evelyn Nelson‑Pennebaker said learning about oxygen requirements and the economics of scale-up broadened her perspective.

“Have to be thinking about costs and other stuff early on if you have any intention of scaling it up,” Nelson-Pennebaker said. “This isn’t the sort of experience you would get in a class or a lab. I’m glad I was able to work with the equipment.”

Industry instructors reinforced the workshop’s multidisciplinary value.

Zachary Baer, Ph.D., Lead Fermentation Engineer at International Flavors & Fragrances (IFF), said, “Students were learning the math and chemistry that goes into fermentation science and then how they play with reactors. The problems we face in biotechnology can’t be solved by a single individual or discipline. IALR provides a great place for people from all different backgrounds to dive into a complex problem.”

Lori Maggio-Hall, Ph.D., senior lead scientist at IFF, guided sessions on microbiology and monitoring microbial health — the practical cues that indicate when organisms are thriving — helping participants connect fundamentals to bioreactor performance.

Virginia Cooperative Extension supported student participation with funding.

“Virginia Cooperative Extension is pleased to partner with IALR, the Virginia Tech Department of Biochemistry, and industry experts to expand student awareness and interest in the field of fermentation and help address industry workforce needs,” said Dan Goerlich, VCE Associate Director for Initiatives. “This program is an excellent example of putting knowledge to work.”

What’s next

With strong feedback from participants over the last two years, IALR plans to continue and expand its training offerings in fermentation and other biotech disciplines. Organizations seeking to enroll employees or learn more about future training sessions can contact the Applied Research team for details.