A Unified Platform for Research, Training and Defense

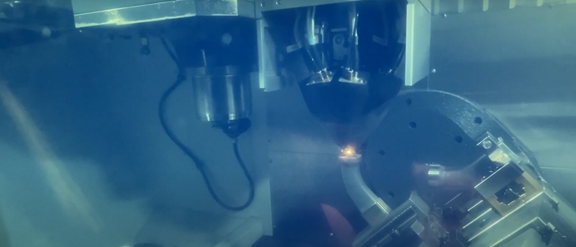

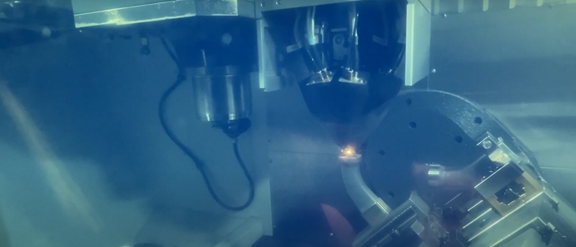

Powered by Meltio’s multi-laser, wire-fed deposition head, IALR’s hybrid systems allow users to create complex metal parts using materials like stainless steel and Inconel — all while retaining the proven reliability and control interface of a 5-axis Haas UMC-750 mill. This integration delivers the dual benefit of world-class subtractive machining with advanced additive capabilities in one compact system.

- Integrated metal part production — combining additive and subtractive processes in one setup

- Hands-on workforce development for advanced manufacturing careers

- Support for defense-sector projects, including shipbuilding, Navy-related repair, and prototyping work

- Collaborative research with academic and industry partners in material science, part design, and production runs.

About the Phillips Additive Hybrid

- Affordable and compact — a fraction of the cost of competing hybrid systems and reduced footprint via integration

- Safe and clean — laser-wire DED is proven safe and cuts waste with near-net shape printing

- Training-ready — includes onsite training and curriculum support from Phillips Hybrid experts

- Flexible — compatible with a variety of Haas CNC vertical mills and additive materials

About IALR

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses on Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg and the cities of Martinsville and Danville.

About Phillips Corporation

Phillips Corporation has been solving manufacturing challenges for over 60 years. Its Additive Hybrid division helps industry and education integrate cutting-edge 3D metal printing into Haas CNC platforms, delivering world-class support, service, and training. Learn more at www.phillipscorp.com/hybrid.