Machine will serve the U.S. Navy’s Additive Manufacturing Center of Excellence.

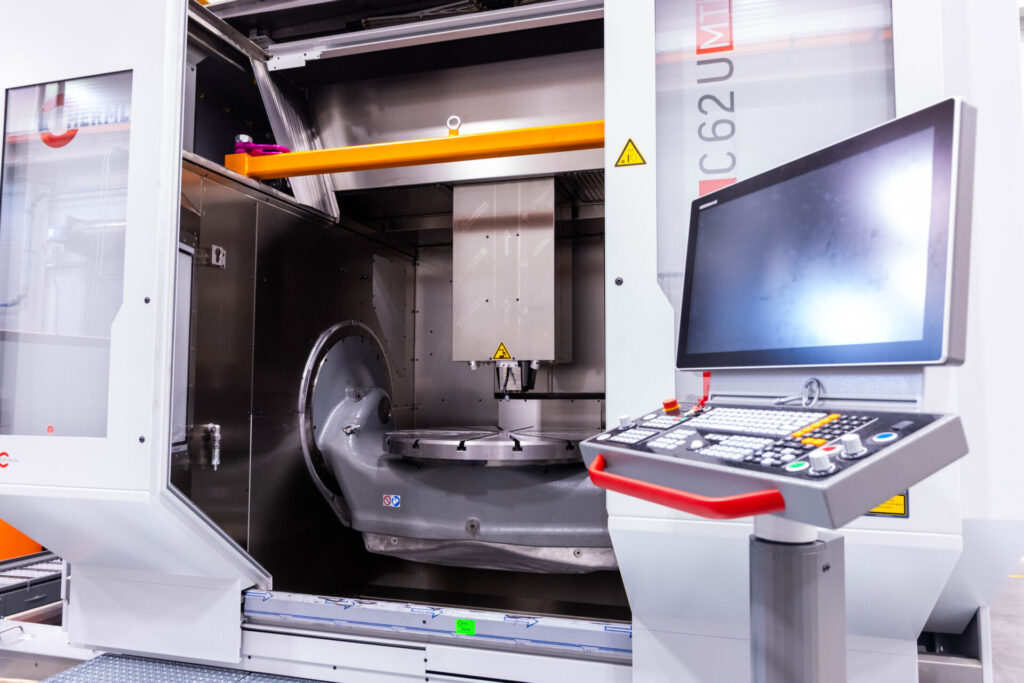

The Institute for Advanced Learning and Research (IALR) has installed a HERMLE C 62 U MT within the CNC Machining Innovation Lab at the Center for Manufacturing Advancement (CMA). Backed by strategic investment from the Maritime Industrial Base (MIB) through Blue Forge Alliance (BFA), this cutting-edge equipment is a critical asset in advancing the mission of accelerating innovation, strengthening industrial capability and enhancing fleet readiness.

This machine will be used for the U.S. Navy’s Additive Manufacturing Center of Excellence (AM CoE) under the guidance of Austal USA as the program’s prime contractor.

As the top model in HERMLE’s High-Performance Line, the HERMLE C 62 U MT is a precision five-axis mill-turn machining center engineered for highly complex parts. It can machine components weighing up to approximately 5,512 pounds, and it features rotational speeds up to 18,000 RPM, rapid linear traverse speeds of 50 meters per minute and a swiveling rotary table that can handle workpieces up to roughly 53 inches in diameter by 43 inches high. HERMLE produces only a few of these specialized models each year, emphasizing their rarity and advanced capability.

This machine incorporates comprehensive fluid technology, optimized chip management, cooling lubricant units and an advanced hinged belt conveyor for efficient chip disposal. Energy efficiency is prioritized through lightweight components, mineral casting technology, energy recuperation and high-quality servo drives, reflecting HERMLE’s commitment to sustainability and performance.

|

|

|

“This is a unique machine, and we are proud to use it to support the U.S. Navy’s additive manufacturing process development efforts.” – Jeremiah Williams, Assistant Director, Technical Innovation & Optimization, IALR

“It’s a dedicated asset to increase advanced manufacturing processes in the AM CoE.” – Kevin Thompson, Assistant Director, Production Operations & Facilities, IALR