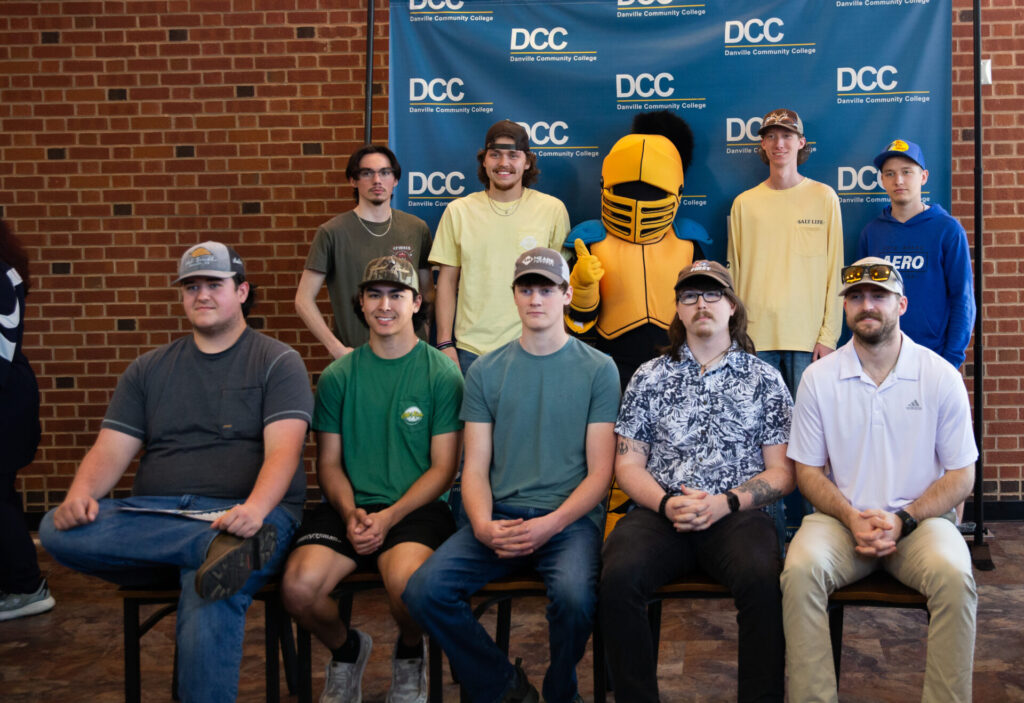

The Institute for Advanced Learning and Research (IALR) and Danville Community College (DCC) are pleased to announce the graduation of the 10th cohort of the Integrated Machining Technology (IMT) program. Over several months, these 14 students refined advanced machining skills while embracing vital leadership and problem-solving practices, preparing them for high-demand roles in today’s modern manufacturing sector.

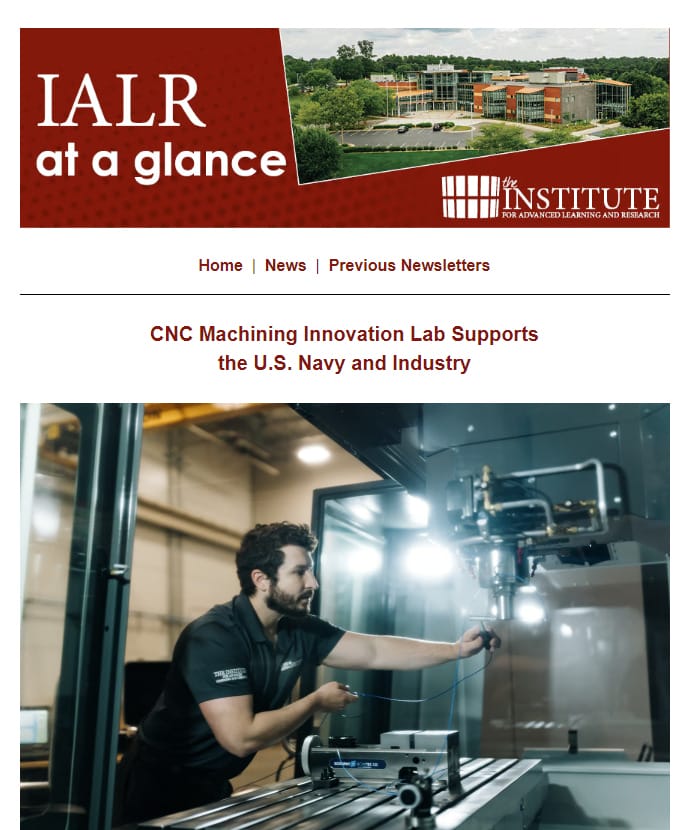

The IMT program is a collaborative effort between DCC and IALR, offering a capstone-style experience that pushes students beyond typical classroom training. They spend time in a simulated “flow cell,” juggling everything from ordering raw materials and scheduling machine operations to conducting inspections on finished products. By taking full responsibility for every stage of production, they gain a strong command of multi-axis CNC programming, Lean/Six Sigma principles and effective teamwork and leadership strategies.

“We see each cohort of IMT students taking real responsibility for the entire manufacturing process, from idea to final inspection. That level of ownership produces confident, capable graduates who are ready to make a difference in advanced manufacturing. IMT graduates train on the latest equipment with industry-informed curriculum, generating the ideal pipeline for career-ready talent.” – Jason Wells, Executive Vice President of Manufacturing Advancement at IALR

“The success of our Integrated Machining Technology graduates reflects the power of hands-on education, industry partnership, and student determination,” said Dr. Cornelius Johnson, Interim President of Danville Community College. “These graduates are stepping into high-demand careers with the skills and confidence to make an immediate impact. We are proud to celebrate their achievements and the role they will play in strengthening our regional workforce.

Throughout the program, students also sharpen soft skills like teamwork, conflict resolution and leadership—competencies that set them apart as they enter their careers.

Graduates of IMT often move on to rewarding positions across industries such as aerospace, automotive and defense. Many choose to stay in Southern Virginia, where their expertise bolsters local companies and helps drive economic development. Over its 10-year history, the IMT program has produced a total of 160 graduates with the skills to positively impact the workforce of regional manufacturing companies.

“This program prepares us for those advancements in technology and manufacturing,” said Parker Turpin, who will be working in a local machine shop. “The program raises the bar higher and higher to prepare students for the actual workforce.”

“It’s definitely been beneficial learning the different manufacturing techniques,” said Jackson Wiles, who is interviewing with multiple companies. “We learned more about the coordinate measuring machines, and I became familiar with three plus two machining, five-axis machining and advanced tool paths.”

MEP—an aerospace firm in IALR’s rapid‑launch space—hired a 2024 IMT graduate full‑time, then took on a 2025 cohort member part‑time during the program; that student now joins MEP full‑time after graduation.

MEP—an aerospace firm in IALR’s rapid‑launch space—hired a 2024 IMT graduate full‑time, then took on a 2025 cohort member part‑time during the program; that student now joins MEP full‑time after graduation.

“The complexity of the work we do at MEP can be demanding, even for experienced CNC machinists, but our IMT students hit the ground running,” said Forrest Ashworth, Operations Manager with MEP. “Their problem-solving abilities, positive attitude, and willingness to go the extra mile have made them strong assets to our team. IMT graduates bring a high level of skill, dedication and professionalism that aligns perfectly with our mission at MEP.”

Founded a decade ago to meet an urgent regional need for higher‑level machining talent, IMT was shaped by local industry and education leaders who saw advanced skills as the key to economic growth. IMT is one of several training programs supported and administered by IALR’s Manufacturing Advancement division.

“We were looking at what would give us a competitive advantage as a region. A group of thought leaders saw that a skilled workforce would be that competitive advantage,” said Troy Simpson, who helped launch the program and later led IALR’s Manufacturing Advancement division.

About IALR

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses on Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg and the cities of Martinsville and Danville.

About dcc

Danville Community College is a two-year institution of higher education under the statewide Virginia Community College System. DCC’s service area includes the City of Danville, Pittsylvania County and Halifax County. For more information about the College’s programs of study, visit www.danville.edu.