The February 20224 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…

- Work-Based Learning opportunities for businesses

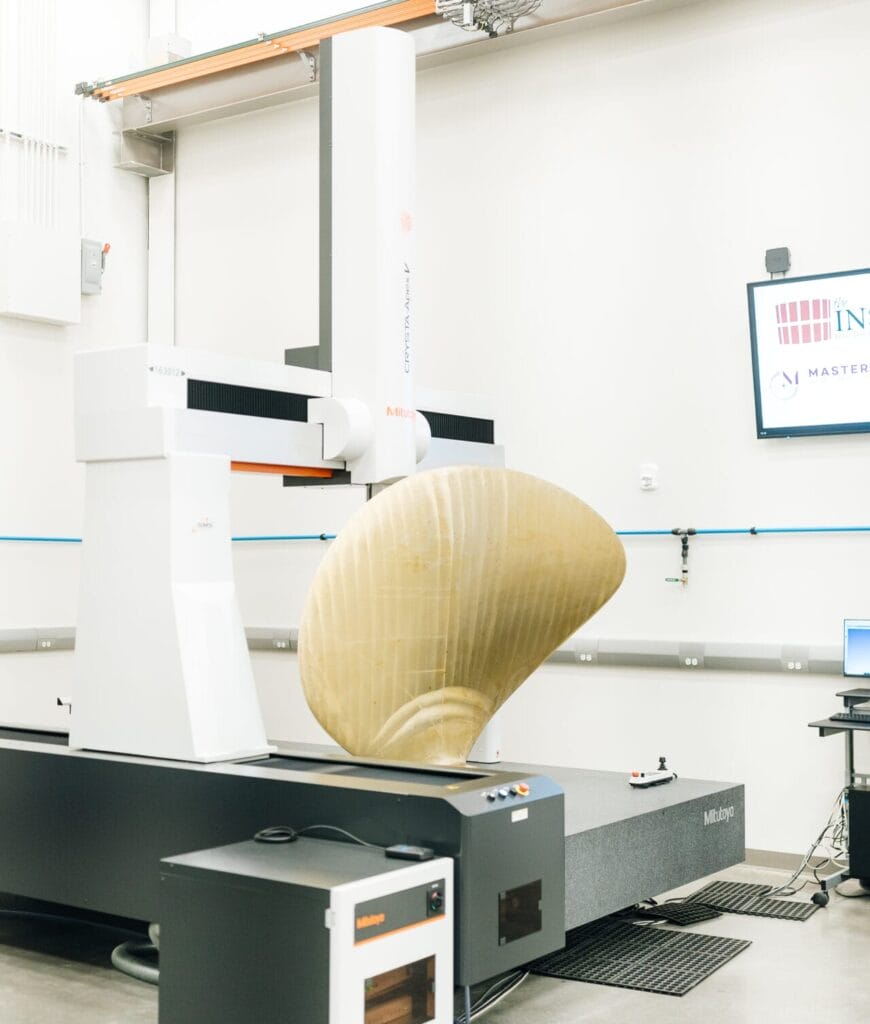

- Top-Tier metrology equipment and services through partnerships

- 2023 Annual Report outlines growing impact

- 81 students graduate from the Accelerated Training in Defense Manufacturing program

- Much more!

Top-Tier Metrology Through Partnerships

Top-Tier Metrology Through Partnerships