Fermentation Fuels the Future

Institute for Advanced Learning and Research

Driving Economic Transformation

Fermentation Fuels the Future

A new feasibility report reveals an emerging opportunity to align two of Virginia’s target sectors—data centers and controlled environment agriculture (CEA)—through strategic co-location. This report was released by non-profit Resource Innovation Institute (RII) in partnership with the Institute for Advanced Learning and Research (IALR) and GO Virginia Region 3.

The report, Co-locating Data Centers and Greenhouses: A Feasibility Report, explores how Southern Virginia can adapt global best practices to create a new model for regional innovation and economic development. Highlighting Agriport A7 in the Netherlands as a leading example, the study outlines how co-locating these industries can unlock resource efficiencies, create high-quality jobs, and enhance community resilience.

“Virginia is strategically building a strong foundation for Controlled Environment Agriculture, driven by innovation and strengthened through public-private collaboration, to position our Commonwealth as a national leader,” said Secretary of Agriculture and Forestry Matt Lohr. “This report shows the potential to create high-quality agricultural jobs in rural Virginia while delivering significant revenue gains for local communities.”

“As data infrastructure expands and CEA continues to gain traction in Virginia, there’s a unique opportunity to plan ahead for smart, synergistic development,” said Derek Smith, Executive Director of Resource Innovation Institute and co-author of the report. “We’re excited to offer this analysis as a roadmap for how Virginia can lead the nation in co-location innovation.”

The study presents a vision for clustered development zones where data centers and greenhouses share infrastructure, such as heat, CO₂, and energy, to reduce costs and improve efficiency. This clustering model, often seen in the Netherlands and Canada, offers a more competitive development plan compared to isolated facilities.

“We are pleased to collaborate with RII and IALR on this pioneering analysis,” said Lauren Willis, Chair of GO Virginia Region 3 Council. “Co-location between data centers and CEA operations represents an actionable, strategic opportunity to strengthen the regional economy while aligning with our long-term development goals.”

This opportunity comes at a time of notable momentum for the CEA industry in Virginia, with Danville emerging as a hub of activity due to research assets like the CEA Innovation Center, robust broadband infrastructure, and ready industrial parks.

“Controlled environment agriculture continues to grow across Southern Virginia,” said Dr. Scott Lowman, Vice President of Applied Research at the Institute for Advanced Learning and Research. “This model of co-location can position our communities to compete nationally while delivering long-term economic and workforce benefits.”

The study recommends evaluating specific co-location sites, launching a demonstration project, and building a coalition to coordinate public-private investment. Drawing on decades of greenhouse management experience, report co-author Rob Eddy, RII’s Horticulturist, emphasizes the importance of aligning infrastructure planning with agricultural and data sector growth to maximize economic and environmental returns.

This research aligns with RII’s broader work through the CEA Accelerator, a U.S. Department of Energy-supported initiative advancing energy- and water-efficient agriculture. By integrating co-location strategies into regional development, the report offers a roadmap for communities like Southern Virginia to pursue resilient food systems, efficient industrial design, and long-term job creation.

Contact: Derek Smith, Executive Director

Email: derek@resourceinnovation.org

About Resource Innovation Institute (RII):

Resource Innovation Institute (RII) is a non-profit shaping the future of food, energy, water, and data systems. Partnering with governments, utilities, industry leaders, and research institutions, RII develops strategies and tools that scale controlled environment agriculture (CEA) as a solution to global food and resource challenges.

Building on work with the U.S. Department of Energy, Lawrence Berkeley National Laboratory, USDA, and state agencies, RII is designing Farm Parks, regional resilience hubs that unite high-tech food production, circular resource sharing, and data infrastructure to achieve economies of scale.

About the Institute for Advanced Learning and Research (IALR)

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts.

About GO Virginia Region 3

GO Virginia Region 3 works to grow and diversify the economy of Southern Virginia by investing in regional projects that drive innovation, workforce readiness, and business growth.

What if you could track a plant’s health and growth every 15 minutes, all automatically and without ever touching it?

In this episode of Inside IALR, Dr. Scott Lowman, Vice President of Applied Research at the Institute for Advanced Learning and Research, explores the SMART Platform—IALR’s Spatially and Mechanically Accurate Robotic Table system. These high-tech tables combine robotics, precision imaging and automation to capture tens of thousands of data points per experiment, helping researchers analyze plant growth, stress response and even subtle movements in real time.

Learn how the SMART Platforms allow for entire plant life-cycle testing for beneficial microbes and enable real-time monitoring of plant health. You’ll hear about how interns have played a central role in coding and refining the system, how companies can contract research on the tables and how this technology is helping lay the groundwork for more sustainable agriculture.

Whether you’re into agtech, robotics, plant biology or data science, this episode connects it all. Plus, you’ll hear how this one-of-a-kind platform is opening doors for students and researchers alike.

🔍 Topics Covered:

The July 2025 edition of IALR at a Glance is packed with exciting news and updates! Learn more about…

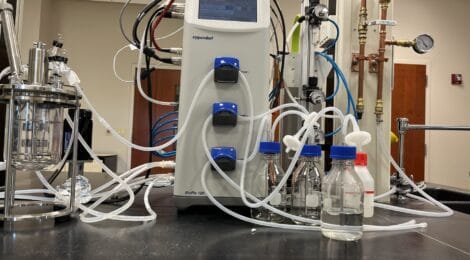

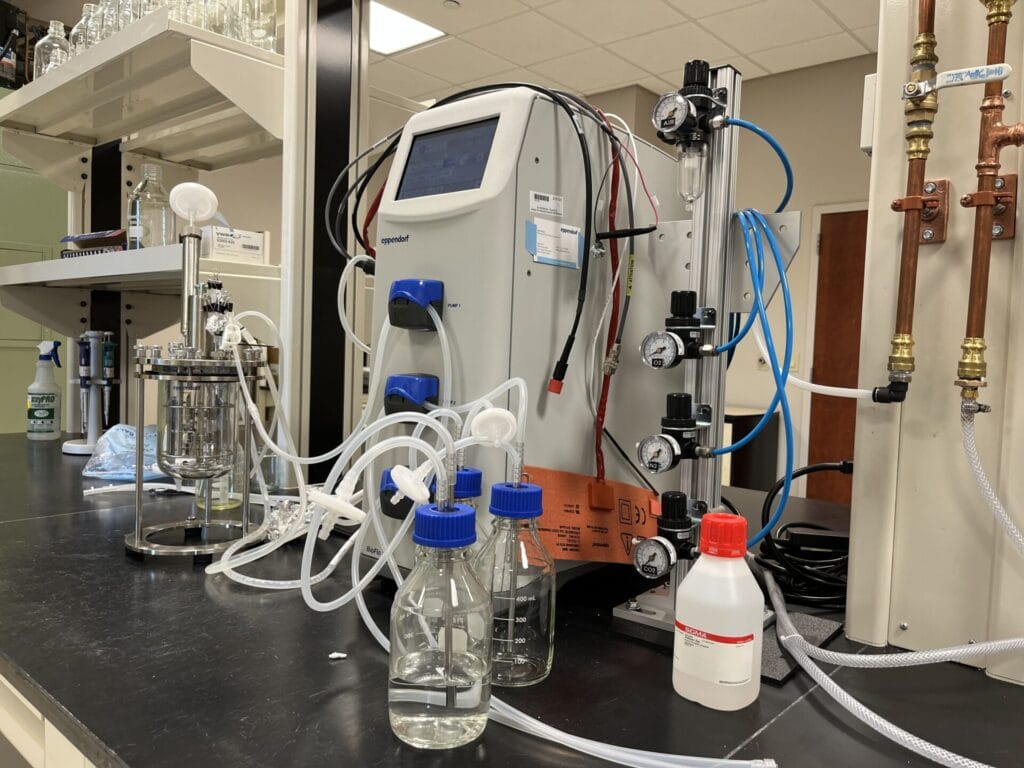

Industrial fermentation, the large-scale use of microorganisms to create valuable products, powers a broad range of industries, from pharmaceuticals to food production. To teach the fundamentals of fermentation to entry-level professionals and students, the Institute for Advanced Learning and Research (IALR) hosted the VT IALR Industrial Fermentation Workshop Builds Skills on Jan. 13-17.

Co-taught by Dr. Scott Lowman (Vice President of Applied Research at IALR), Dr. Biswarup Mukhopadhyay (Professor in Virginia Tech’s Department of Biochemistry) and industry experts, this five-day, hands-on workshop served participants ranging from community college students to seasoned professionals seeking new skills.

The result was a blend of classroom instruction, laboratory experiments and real-world insights into scaling up microbial processes.

“We’re so thrilled to host the workshop here at IALR. It’s an excellent opportunity for us to bring academic experts and industry together for a hands-on, fast-paced introduction to industrial fermentation.” – Scott Lowman, Ph.D., Vice President, Applied Research, IALR

Biswarup Mukhopadhyay, Ph.D., Professor, Virginia Tech Department of Biochemistry

Fermentation processes draw on microbiology, chemical engineering and more—disciplines that must align for the successful development of commercial-scale products. Participants explored how small-scale lab work translates to large industrial fermenters and bioreactors.

“A student might develop a process in the lab on a Petri plate or in a small flask. When it scales up, sometimes it doesn’t work the same way. Part of this workshop is learning what precautions to take early on so the process will translate well to a larger reactor.” – Biswarup Mukhopadhyay, Ph.D., Professor, Virginia Tech Department of Biochemistry

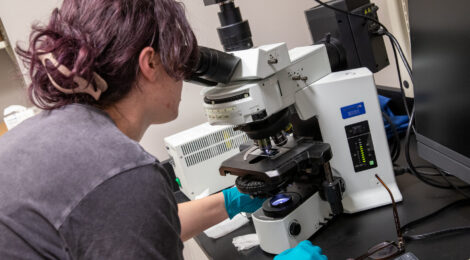

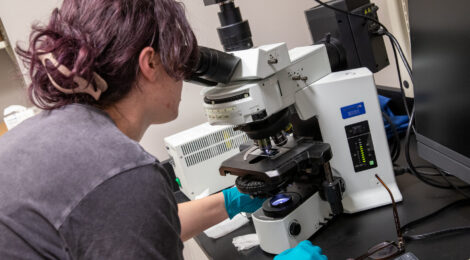

Participants spent significant time operating bench-scale bioreactors, adjusting variables like temperature and pH and collecting real time data. Industry partner Distek Inc. provided some equipment for students to practice what they learned.

“Many training courses focus a lot on theory and lectures, which is great. You get foundational knowledge that way, but solidifying it and running the systems with microbes drives home those concepts we learned in the lecture. The ability to go back and forth between the two sets these students up for understanding how the industry works, not only from a conceptual side but when they run the small-scale bioreactors.” – Justin Cesmat, Product Line Manager, Distek

Justin Cesmat, Product Line Manager, Distek

Attendees ranged from undergraduate students aiming to break into biotech to seasoned professionals exploring new skills. They praised the workshop’s focus on real-world applications and its clarity for potential career paths.

“The workshop was wonderful. Now I have a better perspective on industry and what it takes to get from education into the field.” – Skyler Gentry, Biotechnology Student, Virginia Western Community College

Skyler Gentry, Biotechnology Student, Virginia Western Community College

“It’s been a comfortable learning experience. I think this is a great starting point for fermentation training. This is a good skill for any scientist to have.” – Udipta Bihari, Student, Virginia Tech

“This workshop has been good to teach. We have people who have never worked with fermenters and those in the field who are looking to commercialize from industry, and then students who are learning how things they’ve been doing on a small scale could be brought into their future careers as they think about how to commercialize something they’re learning in the lab.” – Zach Baer, Ph.D., Fermentation Specialist, IFF

With the successful conclusion of this inaugural workshop, IALR plans to expand this type of collaborative training offerings in fermentation and other biotech-related areas. Organizations seeking to enroll employees or learn more about future training sessions can contact the Applied Research team for details.

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg, along with the cities of Martinsville and Danville.

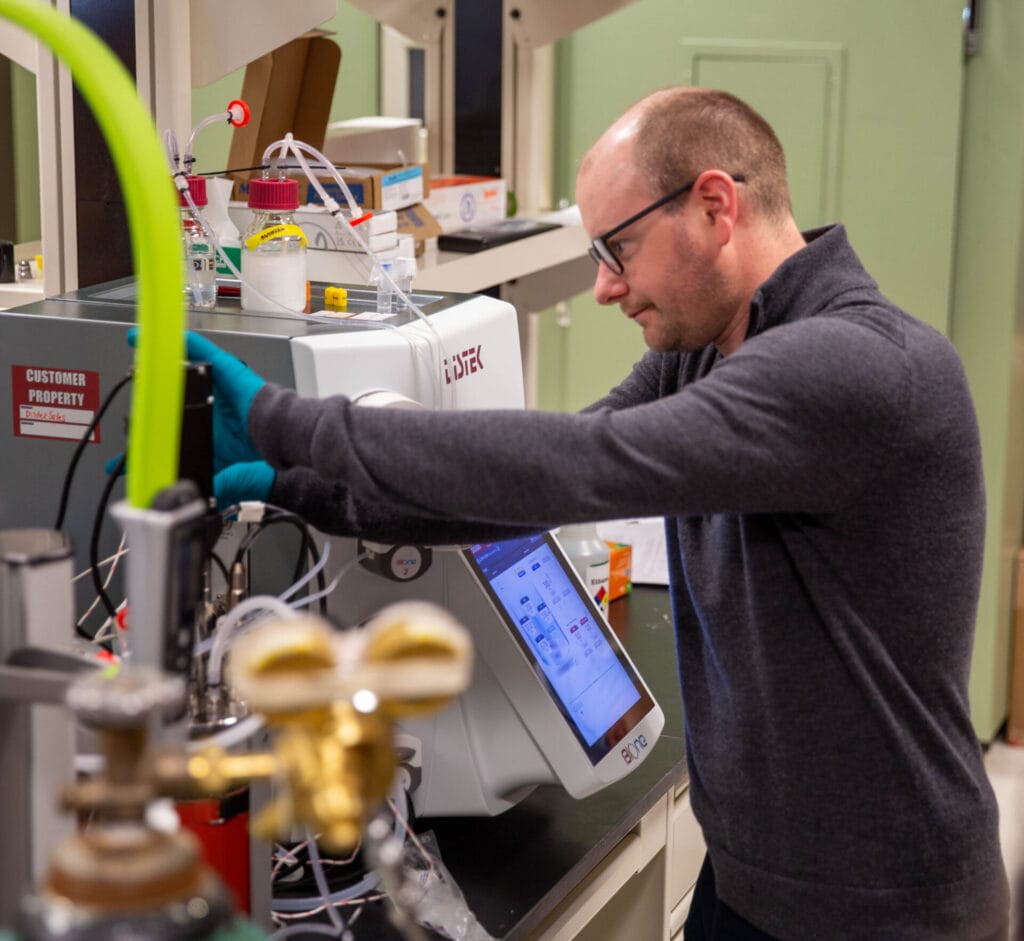

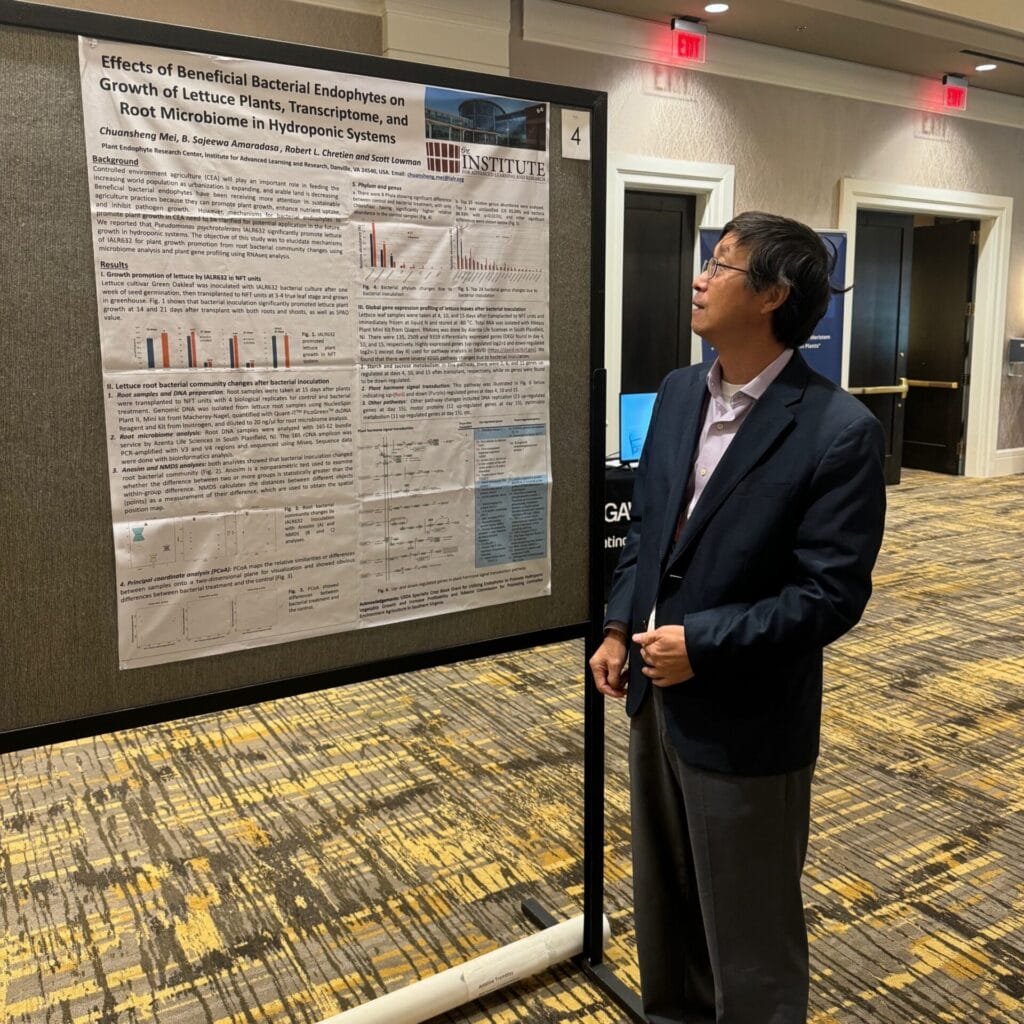

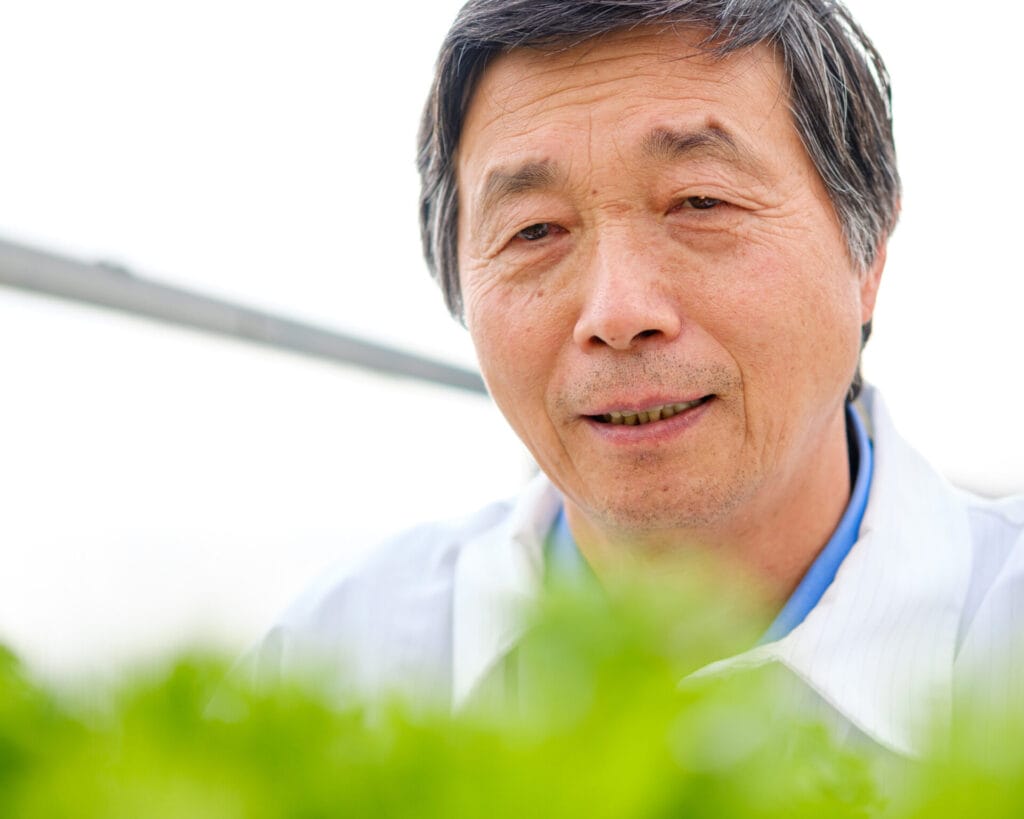

Two scientists from the Institute for Advanced Learning and Research (IALR) presented research at the 11th Plant Genomics & Gene Editing Congress and the 8th Partnerships in Biocontrol, Biostimulants & Microbiome Congress held in Raleigh, N.C. Dr. Chuansheng Mei and Dr. Sajeewa Amaradasa showcased posters highlighting the results of their research into the effects of biostimulants and biocontrol agents on hydroponic lettuce and cucumber production, respectively.

|

|

Dr. Amaradasa’s poster was selected as a winner in the poster competition, and he was then invited to present it during the congress.

Dr. Amaradasa showcased his work on “Biological Control of Pythium in Cucumber and Hydroponic Lettuce by Endophytic Pseudomonas Strain IALR1619.” Pythium is a persistent pathogen affecting cucumber and lettuce in indoor agriculture. Dr. Amaradasa’s study, published in PLOS ONE, found that treating these crops with a naturally occurring biocontrol agent improved plant survival rates and increased overall yield.

“Biocontrol agents offer a powerful alternative to chemical fungicides,” said Dr. Amaradasa. “Our work demonstrates that we can maintain effective disease control while minimizing ecological impact, which is essential for sustainable agriculture.”

Dr. Mei presented his research titled “Effects of Beneficial Bacterial Endophytes on Growth of Lettuce Plants, Transcriptome and Root Microbiome in Hydroponic Systems.” His findings, developed through a three-year collaboration with Virginia Tech and Appalachian State University, demonstrate how introducing a naturally occurring biostimulant can boost lettuce yield by 15-20% and significantly enhance root development.

“Our research is focused on providing growers with natural, effective tools to boost plant productivity,” said Dr. Mei. “The results show real promise for expanding sustainable food production in hydroponic systems, which is crucial as we look for ways to feed a growing population.”

The Plant Genomics & Gene Editing Congress focused on advancements in plant genomics and gene editing, with case studies on enhancing disease resistance and stress tolerance in critical crops. The congress also covered computational phenotyping, bioinformatics integration and the potential of artificial intelligence in plant research.

The 8th Partnerships in Biocontrol, Biostimulants & Microbiome Congress examined the development of agricultural biopesticides and biostimulants, focusing on plant microbiomes and their role in improving crop yield and stress tolerance. The event featured discussions on symbiotic plant-microbe relationships and regulatory updates for biological products.

The event provided a platform for IALR’s Applied Research team to share their cutting-edge work at the intersection of technology and agriculture, demonstrating how endophytes and other beneficial microorganisms can enhance productivity and sustainability.

“Our mission at IALR is to drive economic transformation, and our research team does that by meeting the needs of industry and producers,” said Dr. Scott Lowman, Vice President of Applied Research. “We are committed to providing unique services and sustainable solutions in biotechnology, controlled environment agriculture and analytical chemistry.”

The October 2024 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…

Building on the success of previous years, the third annual Controlled Environment Agriculture (CEA) Summit East returned to the Institute for Advanced Learning and Research (IALR) Conference Center in Danville, VA, from October 1-2, 2024. Co-hosted by Indoor Ag-Con and the CEA Innovation Center—a joint project with Virginia Tech’s School of Plant and Environmental Sciences, IALR and the Virginia Seafood Agricultural Research and Extension Center —the event attracted 230+ attendees from 35 US states, Canada, the Netherlands, and Hong Kong. The diverse audience of growers, educators, scientists, Extension personnel, suppliers, tech specialists, and government leaders gathered to explore the latest advancements in CEA technology and build valuable partnerships.

The two-day event featured a packed agenda of keynote presentations, panels, breakout sessions, and tours of the CEA Innovation Center facilities. Attendees had the opportunity to engage with 21 tabletop exhibits showcasing cutting-edge innovations and services shaping the future of CEA. Alongside these sessions, a range of networking opportunities fostered new connections and strengthened existing partnerships.

“We’re proud to see the CEA Summit East improve year after year. The diversity of expertise represented here is impressive, and it’s a testament to the collaborative nature of this growing sector.” – Brian Sullivan, CEO of Indoor Ag-Con

“It’s inspiring to see leaders across the CEA spectrum come together to exchange ideas and strategies that drive our industry forward. This event underscores the importance of partnerships and shared knowledge in achieving the growth and success we envision for CEA.” – Dr. Scott Lowman, Co-Director of the CEA Innovation Center, Vice President of Applied Research, IALR

Virginia Governor Glenn Youngkin, a steadfast supporter of the indoor agriculture sector, kicked off the event with the opening morning keynote address. His session was immediately followed by the session, “What Is CEA: It’s Mission, Definition and Purpose,” with Paul Brentlinger, CEO, CropKing, Inc.; Jessica Soare, Senior Director of Marketing, BrightFarms; Mike Ross, Co-Founder & CEO, Beanstalk; and Dr. Michael Evans, Virginia Tech and Co-Director of the CEA Innovation Center. On the second day, the Leadership Insights Panel welcomed Carl Gupton, CEO, Greenswell Growers; John McMahon, Co-Founder & COO, Better Future Farms; Molly Montgomery, Acting CEO Executive Chair, AeroFarms and moderator Emily Gee, CEA Alliance Board Member and Marketing Director, AeroFarms, to the stage,

|

|

|

The CEA Summit featured three educational tracks – Production, Business and Education, Workforce and Training– that brought academics, growers and business experts together covering a wide range of topics ranging from food safety, economics of CEA, crop selection and aquaponics to strategies for energy management, onboarding training programs for new employees, and building international partnerships. Other panel discussions and 15-minute CEA Industry & Research Showcase sessions gave attendees the chance to hear about some of the latest research findings and other industry success stories.

|

|

In addition to conference sessions, attendees had ample opportunities to visit with the Summit’s 21 tabletop exhibitors during coffee breaks, luncheon roundtables and an afternoon cocktail reception.

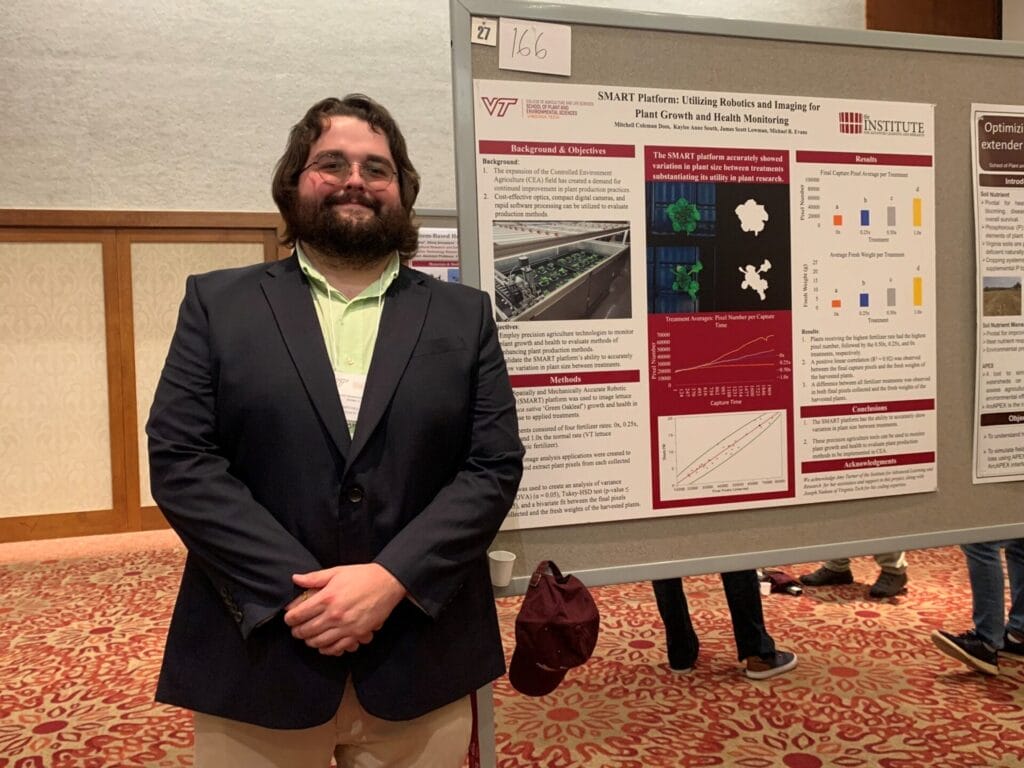

This year’s summit hosted the 2nd CEA Graduate Student Poster Competition to provide an opportunity for graduate students to share high-quality CEA-related research; to expose commercial companies to qualified candidates; and to foster collaboration between individuals in academia and in private industry. Eight finalists competed, and Liam Reynolds, University of Illinois Urbana-Champaign, took first prize for his poster, “Evaluation of Radish, Broccoli, and Lettuce Microgreens Irrigated with Hydrothermal Liquefaction Aqueous Phase.” Nathaniel King-Smith, The Ohio State University, was awarded second place for his poster, “Exploring Sustainable Alternatives for Critical Materials: Hydroponic Cultivation of Rubber Dandelion (T.kok-saghyz) for Rubber Production.”

|

|

The next edition of CEA Summit East will be held September 9-10, 2025. Look for more information coming soon to the event website – www.ceasummit.com. In addition, save the dates for the next edition of Indoor Ag-Con, March 11-12, 2025 at the Westgate Las Vegas.

Founded in 2013, Indoor Ag-Con has emerged as the largest trade show and conference for vertical farming | greenhouse | controlled environment agriculture. Its events are crop-agnostic and touch all sectors of the business, covering produce, legal cannabis | hemp, alternate protein and non-food crops.

The Virginia Tech-IALR Controlled Environment Agriculture Innovation Center is a joint project with Virginia Tech’s School of Plant and Environmental Sciences, IALR’s Applied Research division and the Virginia Seafood Agricultural Research and Extension Center. By developing strategic partnerships with both industry and academia, the goal of the Innovation Center is to conduct research and educational programming to develop, promote and advance the CEA sector in the U.S. and internationally.

Indoor Ag-Con and the Controlled Environment Agriculture (CEA) Innovation Center – a partnership between IALR and Virginia Tech – are pleased to announce that Virginia Governor Glenn Youngkin will deliver the opening keynote address at the CEA Summit East, taking place in Danville, Virginia, on October 1-2, 2024. Governor Youngkin’s keynote will kick off the summit on the morning of October 1st, setting the stage for two days of dynamic discussions, research showcases, tabletop exhibits and collaboration within the indoor agriculture industry.

Governor Youngkin has been a steadfast supporter of the indoor agriculture industry, advocating for the combination of state investment, new technology, and company development to create a thriving ecosystem in Virginia. His commitment to fostering an environment that supports safe, sustainable, and locally grown food makes him an ideal keynote speaker for this year’s summit.

“We are thrilled to have Governor Glenn Youngkin open our conference with his keynote address. Governor Youngkin’s leadership has positioned Virginia as a premier hub for controlled environment agriculture. His efforts to drive economic growth through strategic investments and partnerships have made the Commonwealth a model for the future of indoor farming.” – Brian Sullivan, CEO, Indoor Ag-Con

Under Governor Youngkin’s administration, Virginia has seen significant economic development in the CEA sector, bolstered by its strategic access to domestic markets, plentiful resources, skilled workforce, and a network of robust public and private partnerships. These achievements have not only reinforced Virginia’s role as a leader in next-generation agriculture but have also paved the way for continued innovation and expansion within the industry.

“Governor Youngkin’s vision for a sustainable and prosperous agricultural future aligns perfectly with the goals of the CEA Summit East. His support for the indoor agriculture industry and his dedication to creating opportunities for growth and development make him an inspiring figure for all of us working in this space.” – Dr. Scott Lowman, VP of Applied Research, IALR and Co-Director, CEA Innovation Center

Governor Youngkin’s journey from humble beginnings to co-CEO of a leading global investment firm, and now as a transformative political leader, exemplifies his dedication to hard work and common-sense solutions. His tenure as Governor has been marked by substantial achievements, including the largest education budget in Virginia’s history and numerous economic investments that have spurred job growth and opportunity across the state.

Returning for its third year, the CEA Summit East will be held from October 1-2, 2024, at the IALR Conference Center in Danville, Virginia. Co-hosted by Indoor Ag-Con, the premier trade show and conference for the vertical farming, greenhouse, and CEA sector, and the Virginia Tech (VT) – IALR CEA Innovation Center, this summit continues to be a key event for industry collaboration and innovation, featuring two days of tabletop exhibits, networking and conference programming.

Building on the success of its 2023 edition, which drew participants from 33 U.S. states, Canada, the Netherlands, and Sweden, the CEA Summit East 2024 is expected to once again unite professionals from academia, business, and technology within the CEA industry. Attendees will include greenhouse growers, urban agriculture operations, vertical farms, outdoor growers exploring hybrid opportunities, educators, scientists, extension personnel and agents, suppliers, engineers, tech specialists, architects/developers, government officials, and other industry members.

Founded in 2013, Indoor Ag-Con has emerged as the largest trade show and conference for vertical farming | greenhouse | controlled environment agriculture. Its events are crop-agnostic and touch all sectors of the business, covering produce, legal cannabis | hemp, alternate protein and non-food crops.

The Controlled Environment Agriculture (CEA) Innovation Center is a joint project between IALR and Virginia Tech’s School of Plant and Environmental Sciences and the Virginia Seafood Agricultural Research and Extension Center. By developing strategic partnerships with both industry and academia, the goal of the CEA Innovation Center is to conduct research and educational programming to develop, promote and advance the CEA sector in the U.S. and internationally.

The September 2024 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…

At its basic level, fermentation is a biological process in which microorganisms, such as bacteria or yeast, are used to create a product of value. The products are then harvested, packaged and sold.

Fermentation has been around for centuries and is commonly known for the creation of food and beverage products like wine and cheese. Modern biotechnology is changing this, and products can range from renewable plastics, fuels, food and much more. While the term fermentation scientifically refers to anaerobic processes, it is used broadly in industry, covering all large-scale industrial microbiological processes and supported by the disciplines of industrial microbiology, fermentation technology and biochemical engineering.

In a laboratory setting, these processes can be conducted in small flasks. With the right technology and expertise, however, they can be executed on an industrial scale to produce various products.

The Applied Research team at the Institute for Advanced Learning and Research (IALR) is leading and hosting a five-day, hands-on workshop (Jan. 13-17) on the science, technology and engineering of fermentation. Designed for entry-level workers in the biotechnology industry, this workshop will be co-taught by Dr. Scott Lowman (IALR’s Vice President of Applied Research) and Dr. Biswarup Mukhopadhyay (a Professor in Virginia Tech’s Department of Biochemistry) through a partnership with the Biochemistry Department in the Virginia Tech College of Agriculture and Life Sciences. The workshop will feature invited instructors from industry.

“This workshop, and our growing work in the industrial fermentation space, reflects IALR’s commitment to facilitating industry-driven, collaborative workforce development programs for the careers of today and tomorrow.” – Telly Tucker, IALR President

Biotechnology is the use of living organisms, cells and biological processes to develop products and technologies for various applications. Healthcare, agriculture and environmental management are a few industries that utilize biotechnology processes.

Fermentation is a fundamental process in biotechnology. It uses microorganisms’ metabolic activities to produce different products.

In short, biotechnology harnesses biological systems and organisms to develop or create products, and fermentation is a crucial technique within this field.

“Industrial fermentation is a mixture of microbiology, biochemistry, chemistry, chemical engineering and fermentation technology. All of these are involved. This is highly interdisciplinary. It’s both science and engineering together.” – Dr. Biswarup Mukhopadhyay, Professor, Virginia Tech Department of Biochemistry

Industrial fermentation processes are used in many different industries, including:

IALR is committed to supporting and managing programs that equip the workforce with the skills and certifications for successful work. Just some of the many collaborative efforts include a systematic work-based learning framework, hands-on career introductions for Virginia middle schoolers, and accelerated training for adults looking to start a career in the advanced manufacturing sector.

IALR’s Vice President of Applied Research, Dr. Scott Lowman, has been exploring options to provide fermentation training for years.

“We wanted to partner to provide training and opportunities to people who may want to change careers or get into the biotech industry at a technician level.” – Dr. Scott Lowman, Vice President of Applied Research, IALR

This five-day workshop will introduce microbiology and engineering aspects of industrial microbial cultures, also known as fermentation, emphasizing technology development and scale-up.

Invited lecturers from industry include:

|

|

|

|

|

Participants will generate, analyze and discuss their own data in a group setting.

The workshop will include:

“This class is focused on how to take a small-scale process that has been developed in the lab and take it into the production stage,” Dr. Mukhopadhyay said.

Companies interested in having employees participate in this workshop should contact Dr. Scott Lowman.

Dr. Lowman and Dr. Mukhopadhyay plan to make this a recurring workshop. And offering occasional workshops is not the end of the support that IALR will provide for the growth of industrial fermentation and the biotechnology industry as a whole.

“It’s an industry we could support beyond just workforce training, but we’re entering it through the workforce training opportunity. As we work with these companies, we may be able to support them with research services as well.” – Dr. Scott Lowman, Vice President of Applied Research, IALR

The Plant Endophyte Research Center at IALR is focused on the use of naturally occurring plant bacteria to help with plant growth promotion and stress response. This is biotechnology in action.

This episode features three of the scientists who run the Plant Endophyte Research: Dr. Scott Lowman, Vice President of Applied Research; Dr. Chuansheng Mei, Chief Scientist; and Dr. Sajeewa Amaradasa, Senior Scientist.

The Institute for Advanced Learning and Research (IALR) is proud to announce a new study that explores the use of plant growth-promoting bacteria to significantly boost spinach yields in controlled environment agriculture (CEA). The article was published in Technology in Horticulture on July 2, 2024.

This research is another example of how bacterial endophytes – naturally occurring biostimulants found in plants – can enhance plant growth, improve nutrient uptake and increase stress tolerance, particularly in CEA.

IALR’s Plant Endophyte Research Center has a library of more than 2,000 characterized bacterial endophytes. The researchers in this study tested two of those strains – officially known as Pseudomonas psychrotolerans IALR632 and Enterobacter asburiae IALR1379 – on two spinach cultivars, ‘Red Snapper’ and ‘Seaside.’

These experiments were conducted in indoor vertical nutrient film technique (NFT) hydroponic systems in the Controlled Environment Agriculture (CEA) Innovation Center, a partnership of IALR and Virginia Tech.

The study revealed that inoculations of these bacteria significantly increased the shoot fresh weight, root growth and leaf greenness of the spinach plants.

Overall, IALR632 proved more effective in enhancing spinach yields, root growth and leaf greenness compared to IALR1379 in indoor vertical hydroponic systems.

The Plant Endophyte Research Center and the CEA Innovation Center are focused on optimizing crop production while minimizing environmental impact. And this is not the first research publication from IALR showing the efficacy of bacterial endophytes in improving plant growth and yields.

The research team has consistently shown that endophytes – which function as natural biostimulants and biocontrol agents – can dramatically and positively affect plants in indoor hydroponic environments.

Other recent findings include:

This research was conducted by a joint team from IALR’s Plant Endophyte Research Center and the CEA Innovation Center:

Mitchell Doss recently joined the IALR Applied Research team in a new full-time position as Value Chain Coordinator. In this role, Doss will be responsible for developing regional systems for aggregating, storing and distributing agricultural products to build capacity within the agricultural industry and allow small producers to access new markets.

Doss started the position in July 2024, but his involvement with IALR goes back nearly a decade.

From Gretna, Doss participated in one of the first cohorts of the Academy for Engineering and Technology (AET) – a dual-enrollment, STEM-focused program for students in Danville Public Schools and Pittsylvania County Schools, supported by IALR and Danville Community College.

While still in the AET program, Doss completed his first summer internship with IALR – working with Dr. Scott Lowman – a Ph.D. candidate at the time who now serves as IALR’s Vice President of Applied Research – on an early iteration of the Spatially and Mechanically Accurate Robotic Table (SMART) Platform. These platforms use automation, precision and technology to track the growth of dozens of plants over a growth cycle. Most of Doss’ work that summer involved setting up experiments and maintaining plants.

Doss went on to Randolph College, majoring in Environmental Sciences with a double minor in engineering and data science – a combination that equipped him to continue working with IALR’s Applied Research division.

In 2019, Doss participated in IALR’s summer internship program again, this time as a college student. While working with a former drone program that used aerial photography for crop and field analysis, Doss flexed – and continued to develop – skills in data analysis and imaging technologies, which he would continue to use with IALR.

“Those internships helped me realize that I really wanted to be in the STEM field,” Doss said.

After obtaining his bachelor’s degree, Doss returned to IALR to work with the SMART platform, but this time as a graduate research assistant employed with Virginia Tech. He conducted numerous experiments and supervised a cohort of interns every summer to improve the technology and capabilities of the SMART technology.

“Much of our work at IALR focuses on developing career pathways for emerging workers across Southern Virginia in support of strategic industry sectors. Mitchell’s career progression is a great example of the ‘student-to-intern-to-employee’ pathway IALR is able to support within our own organization and in partnership with the region’s education institutions and business community.” – Dr. Julie Brown, IALR, Vice President, Advanced Learning

He also provided occasional support for the Controlled Environment Agriculture Innovation Center and for the Plant Endophyte Research Center, even serving as a co-author on a few articles.

“With his combined expertise in plant sciences and technology, Mitchell embodies the essence of what our Applied Research division is all about.” – Dr. Scott Lowman, IALR, Vice President, Applied Research

Doss is in the final stages of his master’s degree and will defend his thesis in the fall. In the meantime, he decided to continue working at IALR, this time in the new role of Value Chain Coordinator. Doss will be focused on developing a regional food system, which will lead to more regional agricultural jobs and economic activity.

“I am thrilled that I get to continue working with IALR, and I am excited to see the impact that I can make in this role.” – Mitchell Doss, Value Chain Coordinator, former intern

CEA Summit Brings Academia and Greenhouse, Vertical Farm, Urban Ag, Other CEA Business Sectors Together To Spur Industry Collaboration, Innovation

The Controlled Environment Agriculture (CEA) Summit East returns to the Institute for Advanced Learning and Research (IALR) Conference Center in Danville, Virginia from October 1-2, 2024. Co-hosted by Indoor Ag-Con, the leading trade show and conference for the vertical farming | greenhouse | CEA sector, and the Virginia Tech (VT)-IALR CEA Innovation Center, a joint project of the IALR and Virginia Tech’s School of Plant and Environmental Sciences and Virginia Seafood Agricultural Research and Extension Center, the summit continues to serve as a premier platform for industry collaboration and innovation.

Building on the success of its 2023 edition, which attracted attendees from 33 US states, Canada, the Netherlands and Sweden, the 3rd Annual CEA Summit East is set to unite professionals once again from academia, business, and technology within the CEA industry. Attendees include greenhouse growers, urban agriculture operations, vertical farms, outdoor growers seeking hybrid growing opportunities, educators, scientists, Virginia Cooperative Extension personnel, suppliers, engineers, tech specialists, architects/developers, government officials, and other industry members.

“Our partnership with the VT-IALR CEA Innovation Center underscores our commitment to fostering an environment where industry leaders and academia come together to drive innovation and explore new opportunities within the CEA sector.” – Brian Sullivan, CEO, Indoor Ag-Con

With a focus on facilitating meaningful connections and knowledge exchange, the summit will feature keynote presentations, panel discussions, networking/breakout sessions, and tabletop exhibits highlighting the latest advancements in CEA technology and practices. Attendees can also look forward to research facility tours, providing firsthand insights into cutting-edge research and development initiatives.

“The CEA Summit serves as a platform for showcasing the collaborative efforts between industry and academia in advancing CEA research and education,” adds Dr. Scott Lowman, Co-Director of the VT-IALR CEA Innovation Center and Vice President of Applied Research at IALR. “We are eager to continue driving the momentum of the CEA industry and providing attendees with valuable opportunities for learning, networking, and growth.”

For more information on the 3rd Annual CEA Summit East, including registration, speaking and exhibit opportunities, visit the event website at www.ceasummit.com.

Founded in 2013, Indoor Ag-Con has emerged as the largest trade show and conference for vertical farming | greenhouse |controlled environment agriculture. Its events are crop-agnostic and touch all sectors of the business, covering produce, legal cannabis | hemp, alternate protein and non-food crops. More information, visit www.indoor.ag.

The Virginia Tech-IALR Controlled Environment Agriculture Innovation Center is a joint project between IALR and Virginia Tech’s School of Plant and Environmental Sciences and the Virginia Seafood Agricultural Research and Extension Center. By developing strategic partnerships with both industry and academia, the goal of the Innovation Center is to conduct research and educational programming to develop, promote and advance the CEA sector in the U.S. and internationally. More information – www.ialr.org/cea

The April 2024 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…

“My favorite part has been seeing the progress of the plants daily. Watching them start as little seeds and then grow into some pretty big plants is very cool.” – Jacob Haymore, Undergraduate Research Technician with the CEA Innovation Center

Working part-time as Undergraduate Research Technicians in the Controlled Environment Agriculture (CEA) Innovation Center, Jacob Haymore and Cameron Dallas have gained valuable experience and supported vital research projects.

A joint project between Virginia Tech and the Institute for Advanced Learning and Research (IALR), the CEA Innovation Center is an agricultural technology training center, research hub and demonstration site that connects academia, industry and producers to move the CEA industry forward. The Innovation Center is housed primarily within a modern greenhouse complex on IALR’s campus.

“Bringing students into this ecosystem for impactful employment opportunities fits the mission of the CEA Innovation Center and will contribute to the growth of the CEA workforce.” – Dr. Scott Lowman, Vice President, Applied Research at IALR and Co-Director of the CEA Innovation Center

Haymore’s position is funded through an internal Virginia Tech College of Agriculture and Life Sciences grant focused on hydroponic herb production. A 2022 Chatham High School graduate on the verge of completing his associate degree in liberal arts from Danville Community College, Haymore did not have much experience working with plants. A family friend told him about the position, and he applied. He started in December 2023 and plans to continue working in the CEA Innovation Center through the summer.

Jacob Haymore, a Danville Community College student working as an Undergraduate Research Technician in the CEA Innovation Center.

“The idea of working in a greenhouse was interesting to me,” Haymore said. “I like that I’m not stuck in an office. I get to be hands-on and active.”

As a kid, Dallas learned about agriculture while helping on his grandmother’s farm. A current accounting student at Averett University hoping to pursue a real estate career, Dallas found the CEA position through Averett’s Center for Community Engagement and Career Competitiveness. Dallas started working in the CEA Innovation Center in September and will conclude his term upon graduation. Dallas’s position is funded through the Virginia Tech School of Plant and Environmental Sciences and focuses on vertical farm and greenhouse projects and greenhouse management tasks.

“I felt like something was missing,” Dallas said. “I was doing the typical senior stuff. This turned out to be a great opportunity for me.”

Cameron Dallas, an Averett University student working as an Undergraduate Research Technician in the CEA Innovation Center.

Dallas and Haymore are supporting research experiments on irrigation rates in microgreens, fertilizer rates for dill and fennel, and several projects on the SMART Tables. Some of their daily tasks include data collection, seed sowing, irrigation, treatment application, data entry and monitoring and adjusting electrical conductivity and pH levels in the hydroponic systems.

“I definitely think this experience will help me in my career, whatever direction I take,” Dallas said.

The students have worked with the entire research team at IALR but primarily report to Dr. Kaylee South, Virginia Tech Assistant Professor of Controlled Environment Agriculture, based at IALR.

“My goal with having undergraduate students working with the CEA Innovation Center is to provide the opportunity to learn about horticulture, controlled environment agriculture, and research. This provides students at this stage in their education the opportunity to explore these areas as potential graduate school majors and career paths, build skills that will be applicable in other industries and learn about the food production/agriculture industry.” – Dr. Kaylee South, Virginia Tech Assistant Professor of Controlled Environment Agriculture

The CEA Innovation Center will continue to recruit and develop undergraduate researchers. Those opportunities are sent directly to colleges and universities in the region when available.

The March 2024 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…