IALR to use the same technology in its classrooms that companies worldwide depend on to embrace digital transformation and drive innovation

The Institute for Advanced Learning and Research (IALR) today announced it has received a grant of software from Siemens Digital Industries Software.

The Institute for Advanced Learning and Research (IALR) today announced it has received a grant of software from Siemens Digital Industries Software.

The software, part of the Siemens Xcelerator portfolio, gives more than 1,000 students access to the same technology that companies around the world depend on to develop innovative products in a wide variety of industries, including automotive, aerospace, machinery, shipbuilding, high-tech electronics and many more. This software will be implemented in two primary programs:

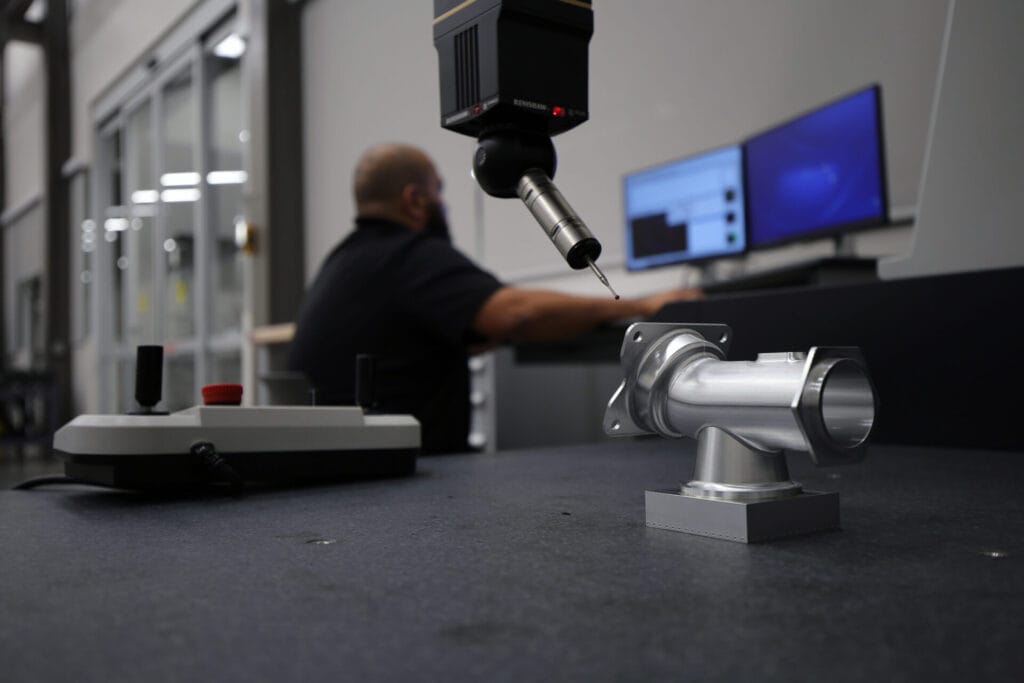

- Accelerated Training in Defense Manufacturing (ATDM): Housed at and instructed by IALR, ATDM prepares adult learners for manufacturing careers that support the maritime industrial base. By 2026, more than 800 students will graduate annually from this four-month program, which trains workers in CNC machining, additive manufacturing, welding, metrology and non-destructive testing.

- Integrated Machining Technology (IMT): A third-year precision machining program offered by IALR and Danville Community College, IMT produces manufacturing leaders with a comprehensive understanding of manufacturing processes and operations and critical leadership skills.

“IALR is excited to have access to industry-leading software in our classrooms,” said Jason Wells, Executive Vice President of Manufacturing Advancement at IALR. “As the industry evolves, our graduates’ STEM skills must also evolve. This technology from Siemens Digital Industries Software will help ensure our students have the relevant digital skills necessary to succeed in Industry.”

Siemens Digital Industries Software is a leading global provider of engineering, manufacturing and electronics software.

The software provided by the Siemens Digital Industries Software academic program delivers technology for different skill levels. Graduates with training, experience and working knowledge of this type of software are highly recruited candidates for advanced technology jobs.

The software for IALR includes the following tools from Siemens Xcelerator:

- Tecnomatix® portfolio, the industry-leading digital manufacturing software

- NX™ software, a leading integrated solution for computer-aided design, manufacturing and engineering (CAD/CAM/CAE) and the Fibersim™ portfolio of software for composites engineering

- Solid Edge® software is an intuitive product development platform for accelerating all aspects of product creation, including 3D design, simulation, visualization, manufacturing and design management

- Simcenter™ portfolio, a robust suite of simulation software and test solutions

- Siemens’ Tecnomatix FactoryCAD is a top manufacturing simulation tool Engineering‘s expert team leverages for customers to improve their planning and production processes.

- Jack is a human modeling and simulation tool that enables you to improve the ergonomics of your product designs and to refine industrial tasks.

- Siemens’ Tecnomatix Plant Simulation is a simulation software used for modeling, simulating, and optimizing production systems and processes.

“Bridging the gap between industry, academia and government is essential to building a sustainable talent pipeline equipped with the advanced skills required for the future of manufacturing,” said Melanie Spare, Director, Academic and Workforce Development. “This partnership exemplifies that mission—by aligning classroom training with the exact tools and technologies used by leading defense manufacturers, we’re not only accelerating workforce readiness, but also reinforcing critical Department of Defense initiatives. Through programs like ATDM and facilities like AM CoE, we’re creating a direct and seamless pathway from learning to doing, ensuring students are job-ready from day one.”

Many of IALR’s Manufacturing Advancement initiatives focus heavily on Department of Defense (DOD) requirements, and this software partnership significantly enhances that alignment. Students in the ATDM program will now train and operate using the same software as leading DOD suppliers, creating valuable continuity between classroom training and real-world defense manufacturing environments. Additionally, several of these Siemens products are already used within IALR’s Center for Manufacturing Advancement (CMA) and the U.S. Navy’s Additive Manufacturing Center of Excellence (AM CoE) due to their compliance with International Traffic in Arms Regulations (ITAR). This further strengthens the synergy between the AM CoE and ATDM, benefiting students by better preparing them for successful careers in defense manufacturing.

About IALR

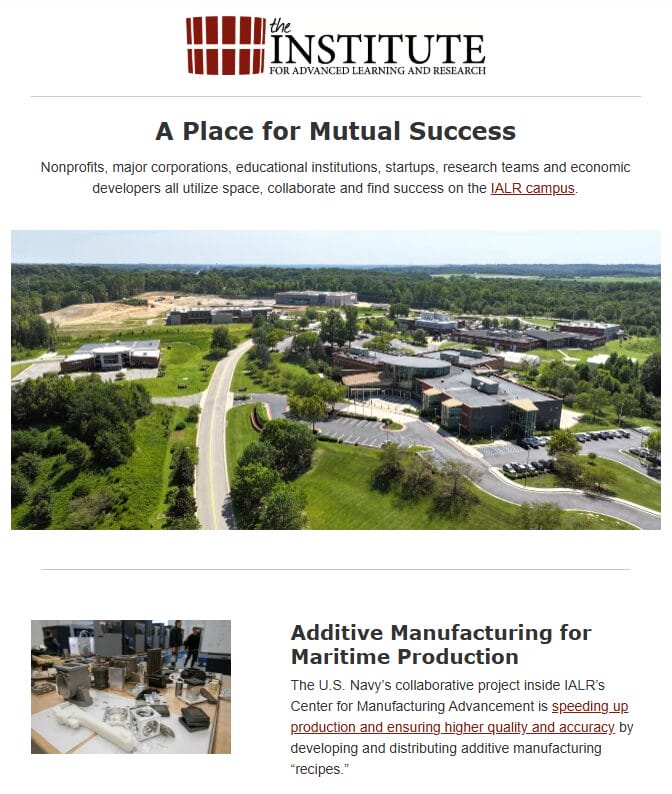

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg along with the cities of Martinsville and Danville.

Note: A list of relevant Siemens trademarks can be found here.

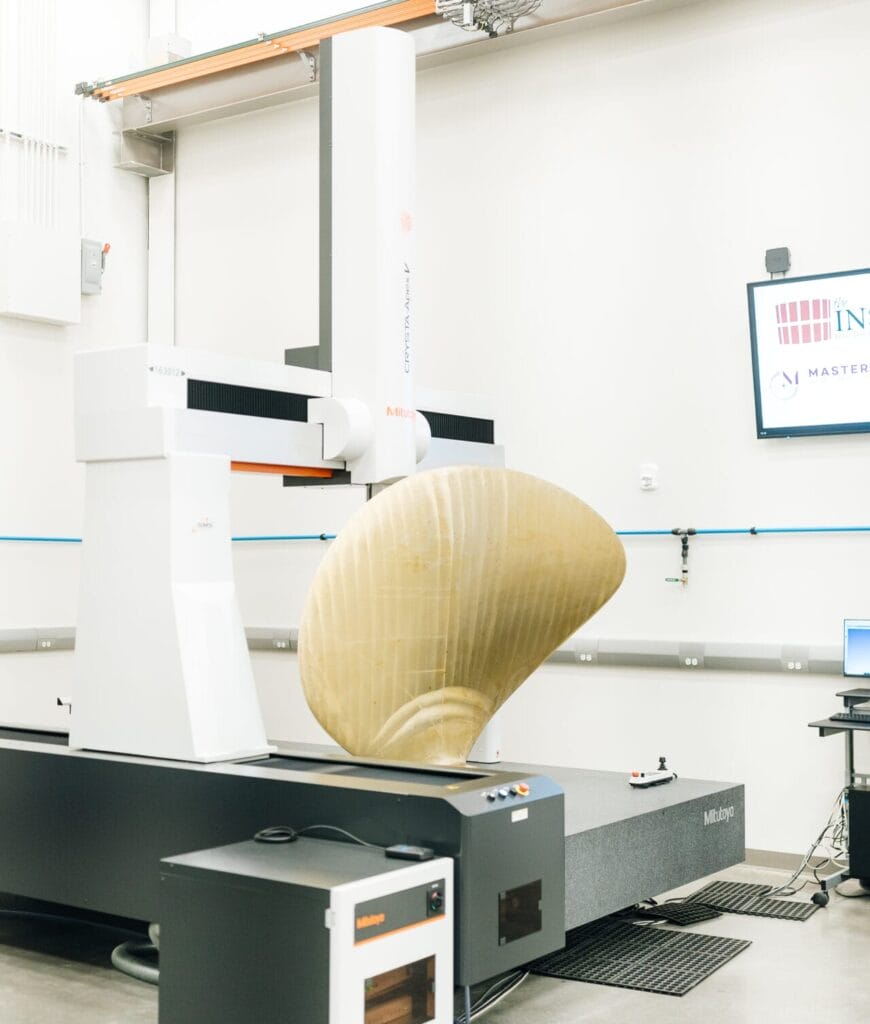

Top-Tier Metrology Through Partnerships

Top-Tier Metrology Through Partnerships

“The events we celebrate today – centered on workforce, technology, and the space where those two priorities must meet – are game changing. The scale and urgency needed in these areas is a fundamental differentiator in our Navy’s ability to preserve peace, and when necessary, compete and win,” added RADM Scott Pappano, PEO Strategic Submarines.”

“The events we celebrate today – centered on workforce, technology, and the space where those two priorities must meet – are game changing. The scale and urgency needed in these areas is a fundamental differentiator in our Navy’s ability to preserve peace, and when necessary, compete and win,” added RADM Scott Pappano, PEO Strategic Submarines.”