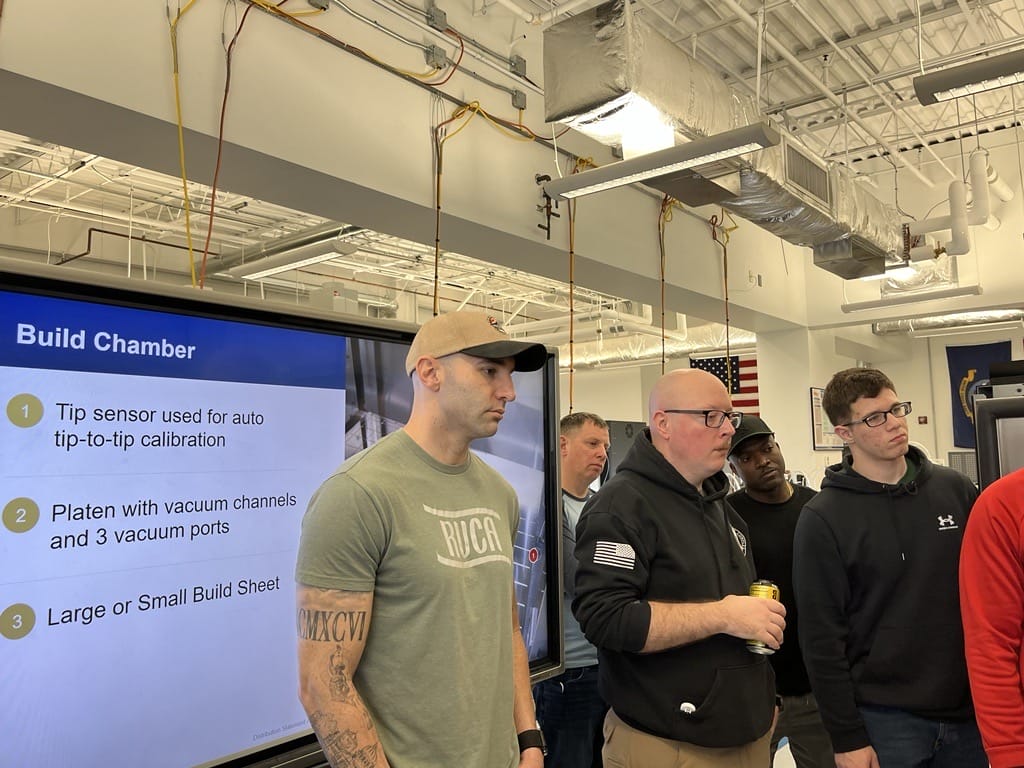

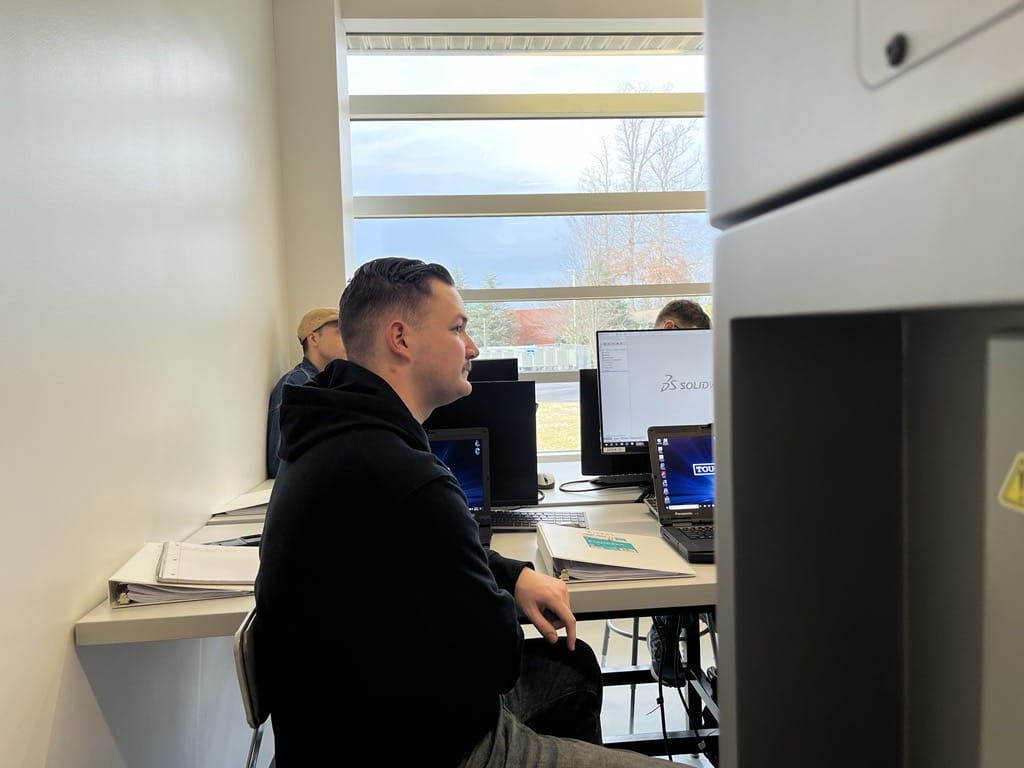

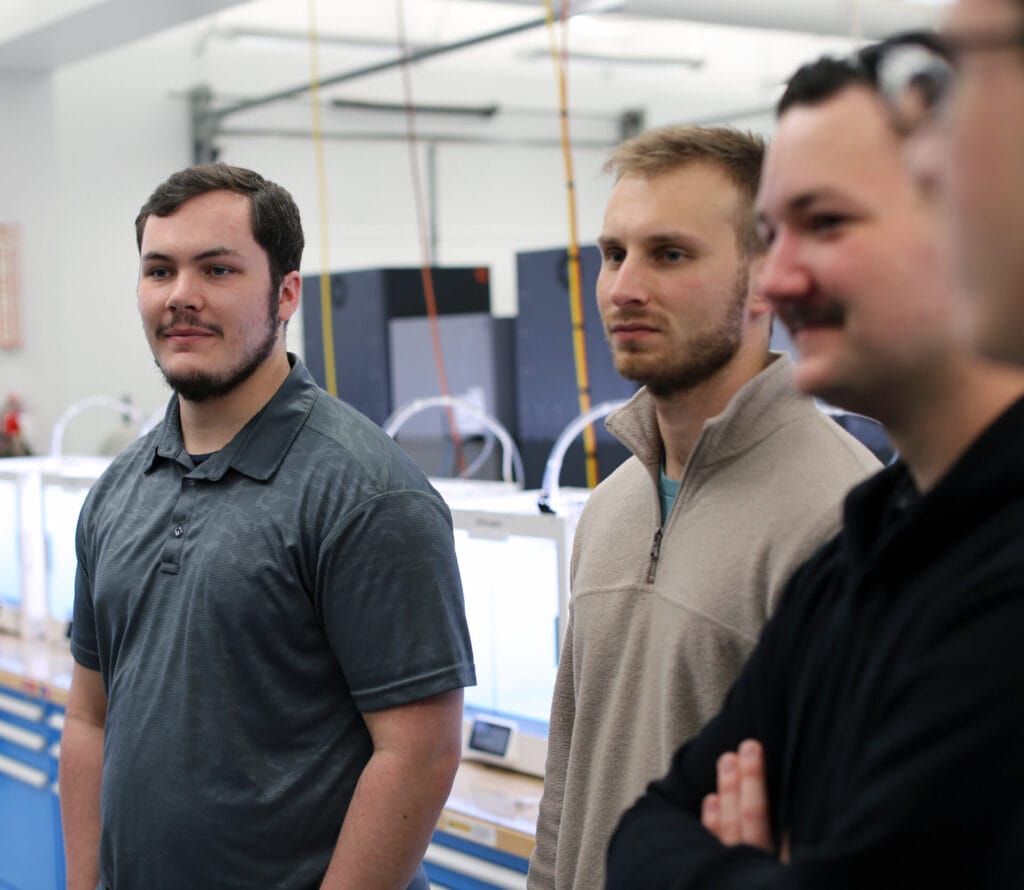

The Institute for Advanced Learning and Research (IALR) celebrated the graduation of the latest cohort of the Accelerated Training in Defense Manufacturing (ATDM) program on Dec. 19. The ceremony honored 42 adult learners who completed intensive training in additive manufacturing and welding — two critical skill sets for building and repairing components within the defense manufacturing sector.

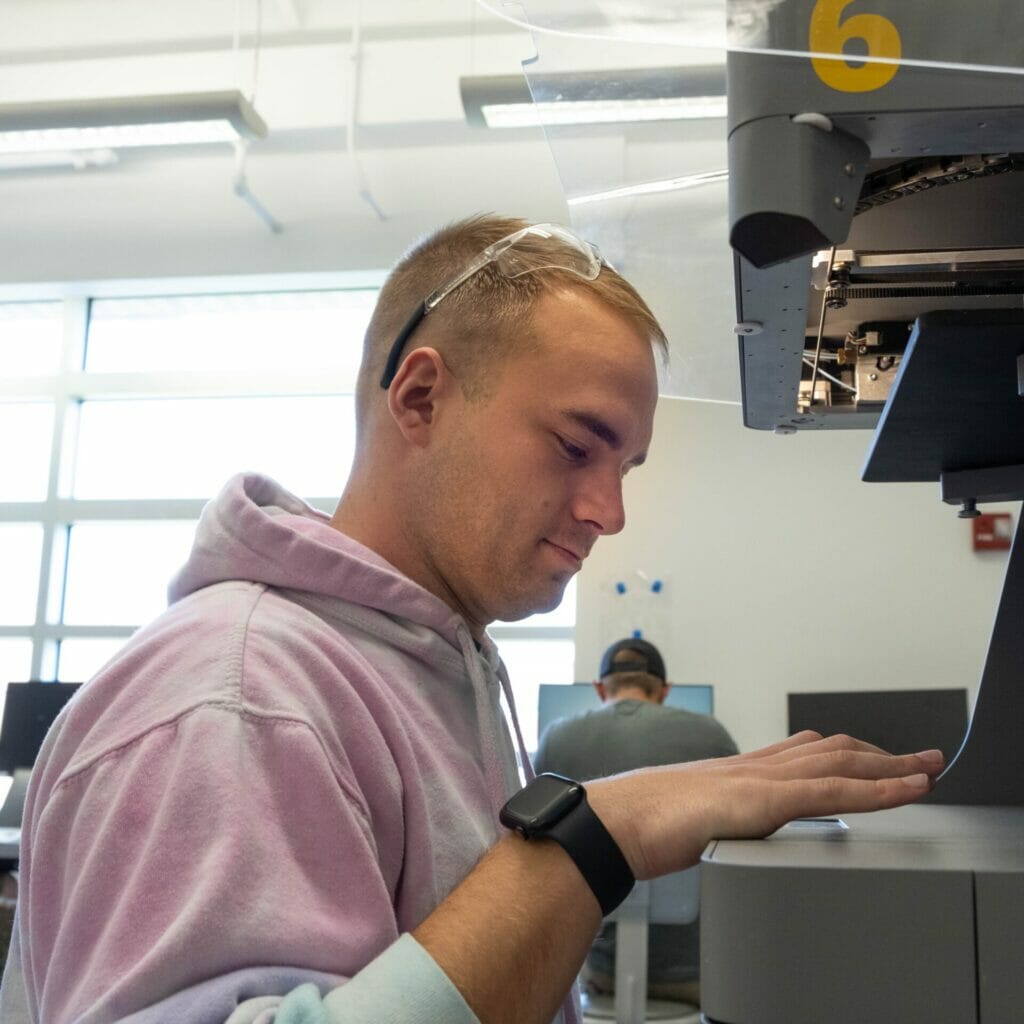

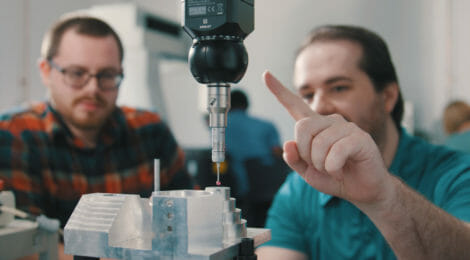

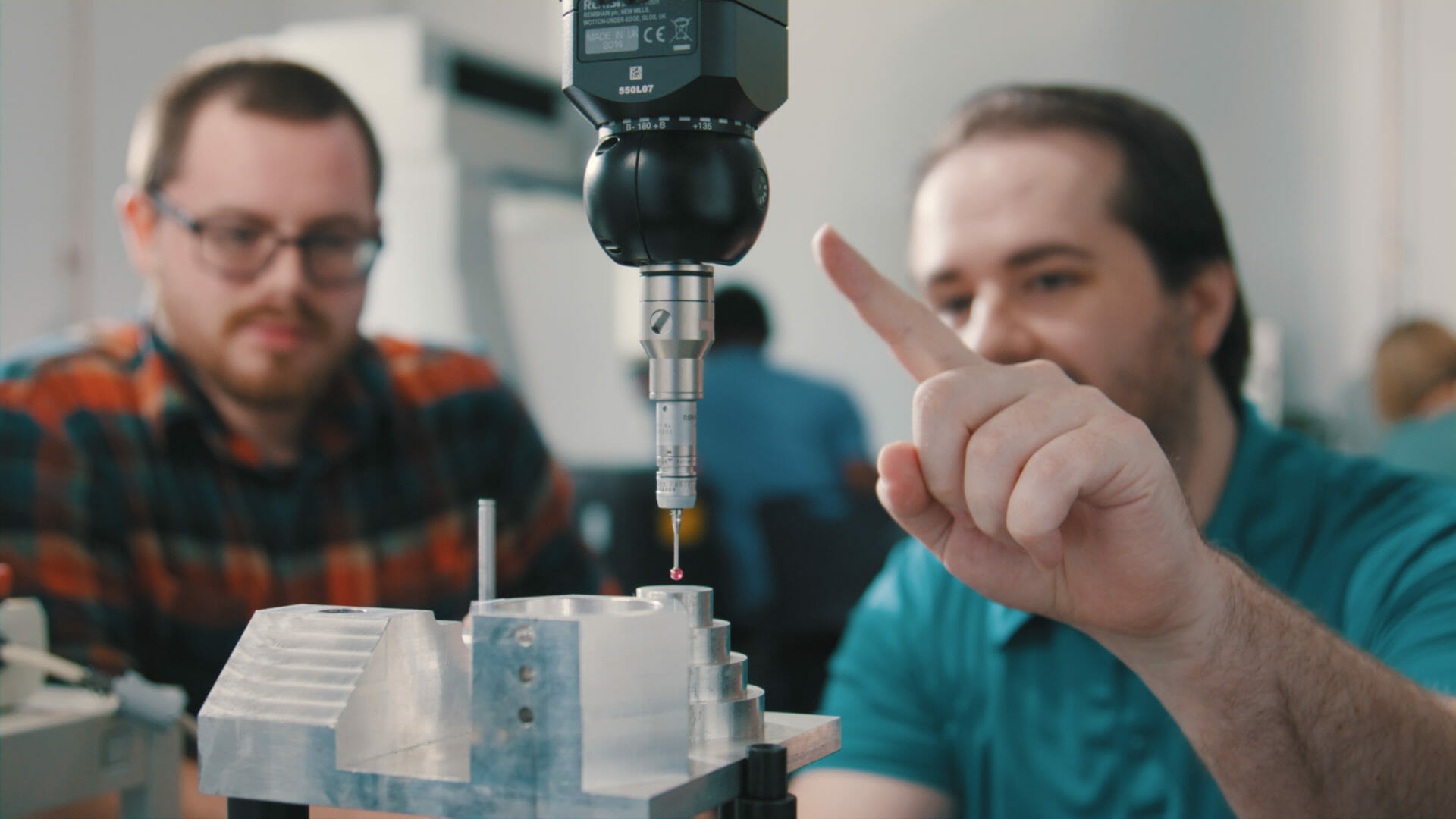

Each completer finished at least 600 hours of hands-on instruction, preparing them for immediate employment within the maritime industrial base (MIB). These tracks equip students with the technical expertise to perform high-precision processes essential to national defense.

Robert McNulty, ATDM welding graduate, shared reflections on the journey through the program.

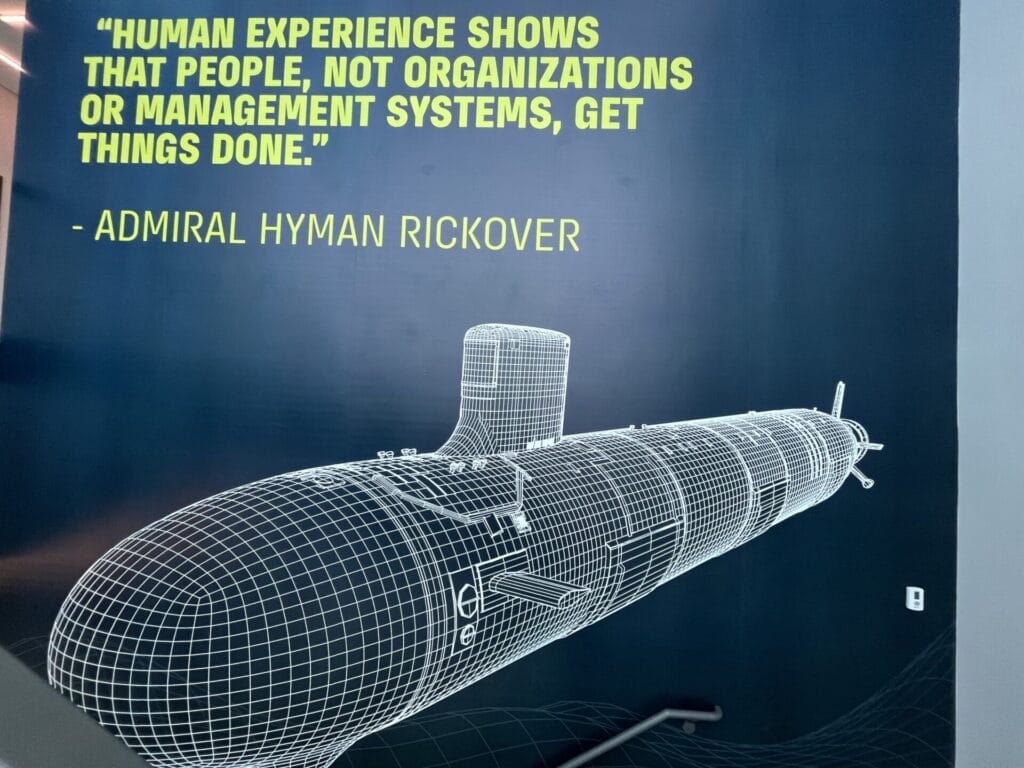

“To my fellow graduates, we are proof that we can rise and meet the expectations. The work we do will hold things together – literally. Ships, structures, systems and communities depend on what we create and join. Let’s take pride in our work, keep learning and never forget where we started.” – Robert McNulty, ATDM Welding Graduate

Retired Rear Admiral Tom Kearney, now working with The Spectrum Group, praised the graduates for their dedication and highlighted the significance of their achievement.

“Each of you is now part of something much bigger than yourselves. You are helping ensure that when our sailors go to sea, the ships will perform as designed, we will win the wars we fight, and they will come home. We trust you, and we need you, and we are counting on you. Congratulations to the graduates of ATDM, and fair winds and following seas.” – Retired Rear Admiral Tom Kearney, The Spectrum Group

Additive Manufacturing Cohort – 2nd Shift

- Andrew Cadena – TX

- Keith Earnshaw – RI

- Kevin Fischer – GA

- Leigh Hanes Jr – VA

- Ekin Huynh – TX

- Gage Jochumsen – FL

- Lauren Rice – MD

- Karlo Torres – CA

Welding Cohort – 1st Shift

- James Crane – IN

- Chris Cranick – IN

- Andrew Hubbs – IN

- John Moreno – FL

- Conner Murray – IN

- Sabrina Newforth – IN

- Hunter Pedrotti – IN

- John Saltares – TN

- Kanaan Worley – IL

- Eric York – IL

Welding Cohort – 2nd Shift

- Brendan Avazis – NY

- Jayden Chase – MD

- Daniel Funderburk – VA

- Colin Gallagher – FL

- Waleed Haddad – NJ

- Kenichi Makino – MD

- Mitchel McLaughlin – NC

- Adlai Miles – TN

- Cameron Owens – SC

- Declin Phillips – NC

- Carsyn Rose – VA

- JaMarcus Shorter – MD

- Oliver Tolin – TX

Welding Cohort – 3rd Shift

- John Brennan – VA

- Matthew Daniell – TX

- Brennan Grice – VA

- Robert McNulty – CA

- Liam Murren – FL

- Jaeden Ortega – PA

- Lakeeshia Pickens – PA

- Trevor Pratt – CA

- Austin Rice – MD

- Elijah Tirado – VA

- Andrew Zimmerman – OH

Participants in the ATDM program benefit from comprehensive scholarships covering tuition and furnished housing. This support enables individuals from diverse backgrounds, including transitioning service members, career changers and industry newcomers, to prepare for and find successful manufacturing careers.

With a goal of training 1,000 students annually, ATDM remains a cornerstone initiative in strengthening the U.S. defense manufacturing workforce. With more than 1,100 total completers to date, ATDM boasts an approximately 85% completion rate and, for completers, an 85% placement rate within 30 days of completing the program.

About ATDM

The Accelerated Training in Defense Manufacturing program provides focused, industry-driven training to equip participants with skills critical for defense manufacturing. This initiative is funded through the National Imperative for Industrial Skills by the Industrial Base Analysis and Sustainment Program Office within the Office of the Undersecretary of Defense for Acquisition and Sustainment.

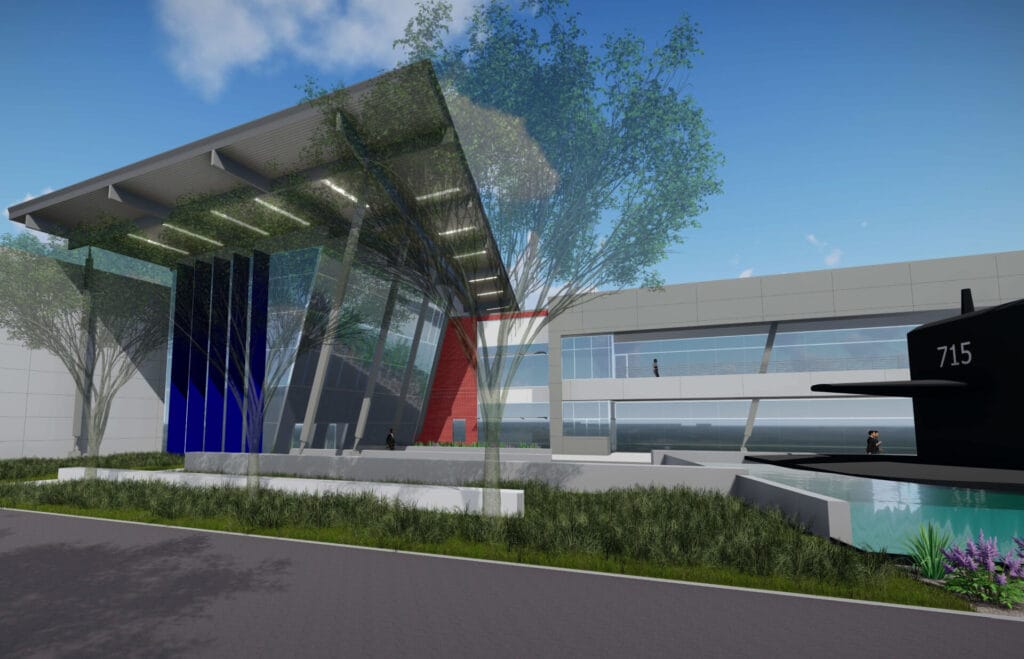

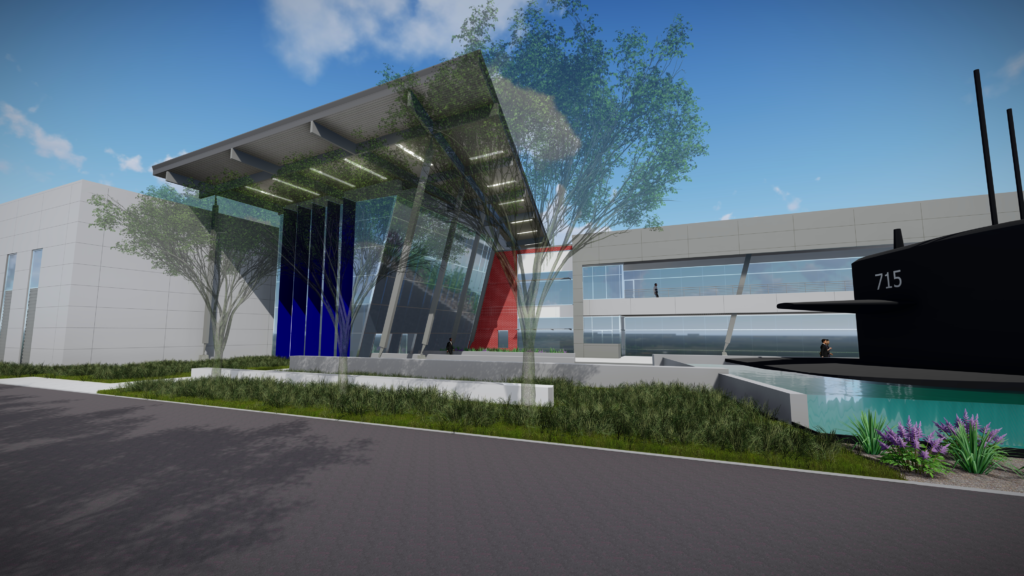

About the Institute for Advanced Learning and Research

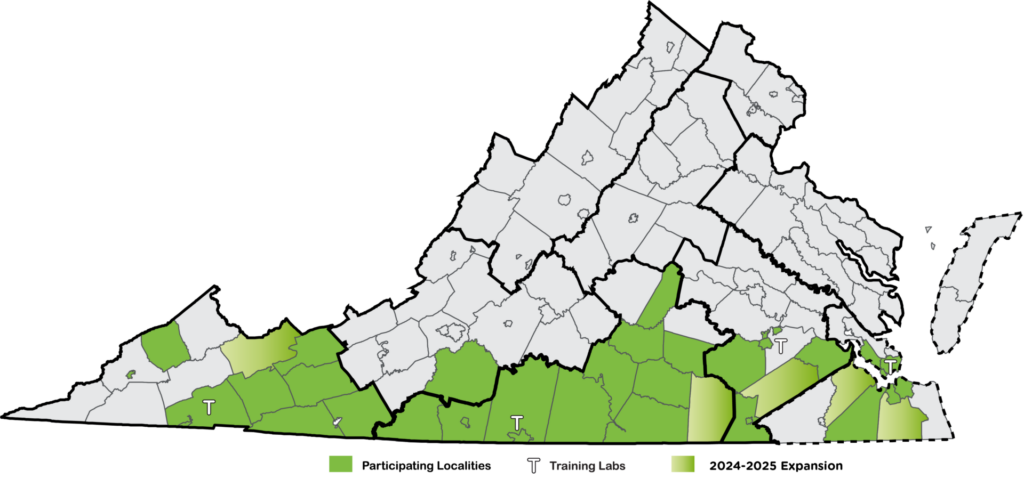

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg along with the cities of Martinsville and Danville. The organization houses and leads the ATDM program with the support of various partners.

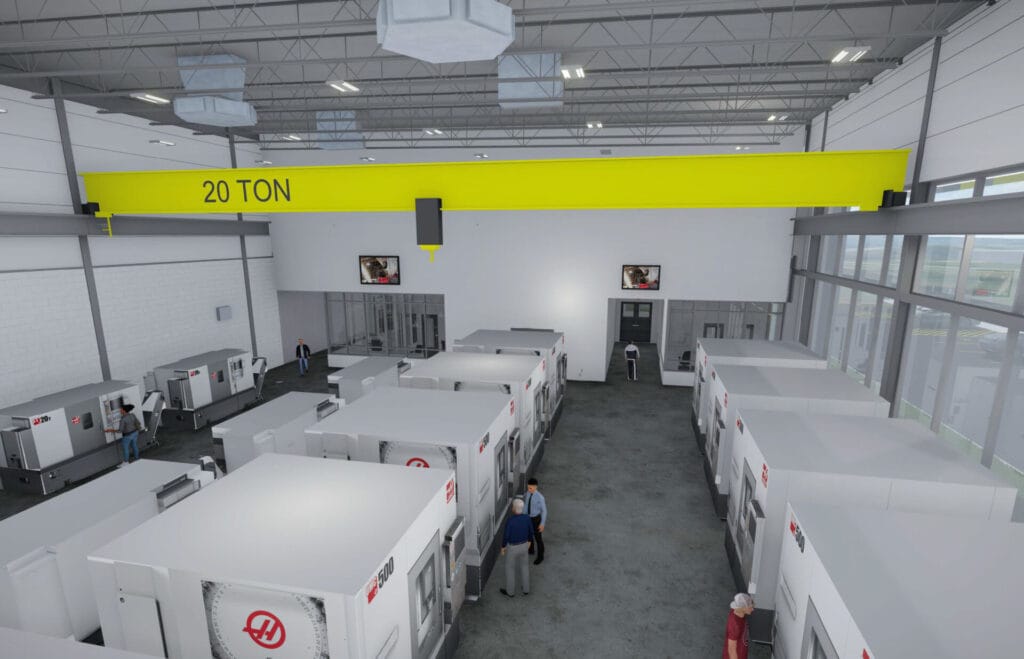

The groundbreaking ceremony was held during the annual ATDM & U.S. Navy Additive Manufacturing Center of Excellence (AM CoE) Summit, which gathered the Navy, Office of the Secretary of Defense, state and local officials, and industry partners to increase awareness of these important initiatives and promote participation and contributions by industry and other stakeholders. This year, ATDM instructors and students were joined by Secretary of the U.S. Navy Carlos Del Toro and Rear Admiral Scott W. Pappano to celebrate the success of the past year and discuss goals going forward.

The groundbreaking ceremony was held during the annual ATDM & U.S. Navy Additive Manufacturing Center of Excellence (AM CoE) Summit, which gathered the Navy, Office of the Secretary of Defense, state and local officials, and industry partners to increase awareness of these important initiatives and promote participation and contributions by industry and other stakeholders. This year, ATDM instructors and students were joined by Secretary of the U.S. Navy Carlos Del Toro and Rear Admiral Scott W. Pappano to celebrate the success of the past year and discuss goals going forward.

“The events we celebrate today – centered on workforce, technology, and the space where those two priorities must meet – are game changing. The scale and urgency needed in these areas is a fundamental differentiator in our Navy’s ability to preserve peace, and when necessary, compete and win,” added RADM Scott Pappano, PEO Strategic Submarines.”

“The events we celebrate today – centered on workforce, technology, and the space where those two priorities must meet – are game changing. The scale and urgency needed in these areas is a fundamental differentiator in our Navy’s ability to preserve peace, and when necessary, compete and win,” added RADM Scott Pappano, PEO Strategic Submarines.”