The March 2024 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…

- REACH Partnership Improving Public Health

- Second GO TEC® Robotics Competition a Great Success

- 190 Student Participated in AspHIRE Mock Interview Day

- Partners Unite for Successful Family Literacy Night at IALR

- Much more!

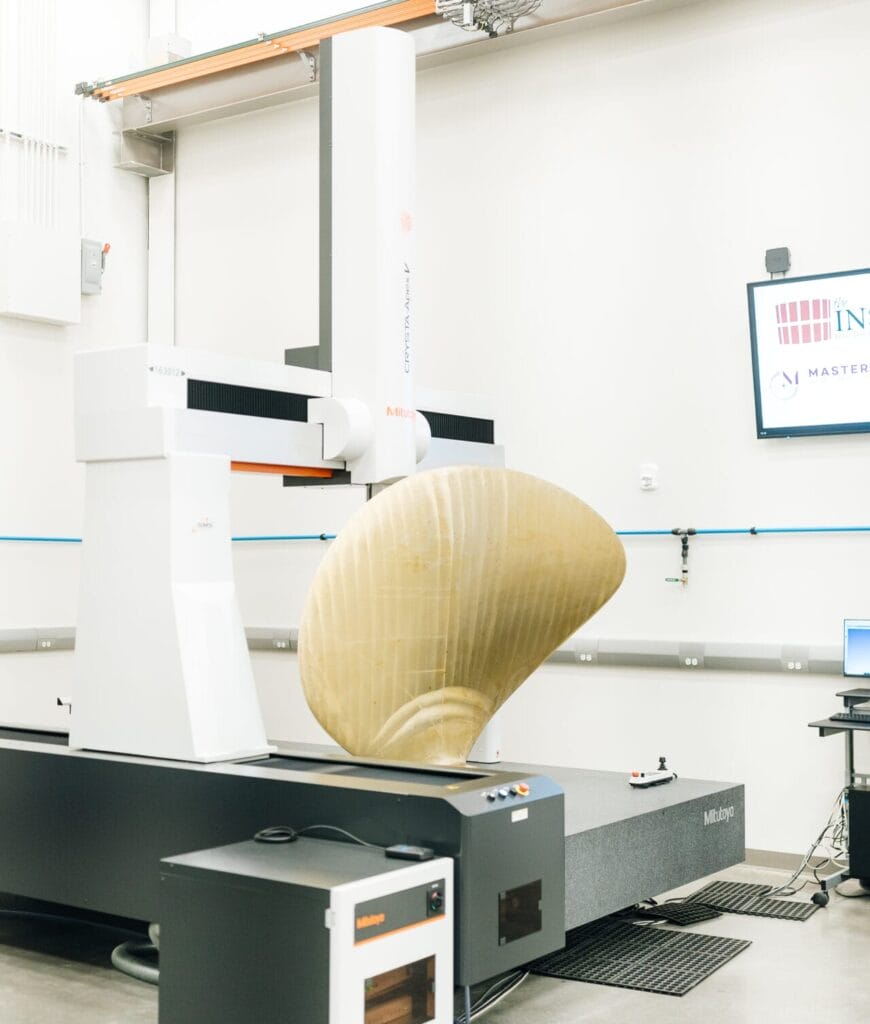

Top-Tier Metrology Through Partnerships

Top-Tier Metrology Through Partnerships