The October 2025 edition of IALR at a Glance is packed with exciting news and updates! Learn more about…

- Fourth Annual CEA Summit East Brings Together 260 Attendees

- IALR Conference Center Offering Holiday Menu

- Watch updates from IALR

- Much more!

The October 2025 edition of IALR at a Glance is packed with exciting news and updates! Learn more about…

The Institute for Advanced Learning and Research (IALR) celebrated the completion of the 19th cohort of the Accelerated Training in Defense Manufacturing (ATDM) program on Oct. 7, 2025. The ceremony honored 20 adult learners who completed intensive training in Non-Destructive Testing (NDT), a critical skill set for ensuring the integrity and safety of components within the defense manufacturing sector.

Each completer finished more than 600 hours of hands-on instruction, earning industry-recognized credentials that prepare them for immediate employment within the Maritime Industrial Base (MIB). The NDT track equips students with specialized techniques to evaluate materials and structures without causing damage.

Student speaker Emery Harris reflected on the transformative nature of the program:

“I wanted a career that challenged me in new ways and gave me skills that really mattered. And that’s what brought me to ATDM,” Harris said. “ATDM has been more than just a training program. It’s been a launchpad. It’s given me the tools, the confidence and the direction that I was looking for.”

Jason Wells, Executive Vice President of Manufacturing Advancement, commended the graduates for their commitment and emphasized the broader impact of their achievement:

“This program is unlike anything else in the country. What these graduates have accomplished is extraordinary—not just in skill, but in resilience. Today, we don’t just recognize them as graduates; we honor them as skilled tradespeople whose work will quietly but powerfully shape the safety, strength and future of our nation. ATDM is more than training—it’s about restoring hope, building possibility and renewing the American dream.” — Jason Wells, Executive Vice President of Manufacturing Advancement

Graduates of the Non-Destructive Testing – 1st Shift

Participants in the ATDM program benefit from comprehensive scholarships covering tuition and housing. This support enables individuals from diverse backgrounds—including transitioning service members, career changers and industry newcomers—to thrive.

With a goal of training over 800 students annually, ATDM remains a cornerstone initiative in strengthening the U.S. defense manufacturing workforce.

The Accelerated Training in Defense Manufacturing program provides focused, industry-driven training to equip participants with skills critical for defense manufacturing. This initiative is funded through the National Imperative for Industrial Skills by the Industrial Base Analysis and Sustainment Program Office within the Office of the Undersecretary of Defense for Acquisition and Sustainment.

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg along with the cities of Martinsville and Danville. The organization houses and leads the ATDM program with the support of various partners.

The Accelerated Training in Defense Manufacturing (ATDM) program is preparing the next generation of skilled workers for the U.S. Navy’s Maritime Industrial Base. With an 85% job placement rate and graduates from nearly every state, ATDM is creating real career opportunities. In this episode, recent graduates Dylan Carter and Angel Gallaher describe how the program equipped them with technical expertise and career-ready confidence.

The September 2025 edition of IALR at a Glance is packed with exciting news and updates! Learn more about…

What is it like to be a woman teaching advanced manufacturing in a field where men make up the majority?

Hear it from three members of the Accelerated Training in Defense Manufacturing (ATDM) instructional team: welding instructor Makayla Baker, metrology instructor Holly Lyle and welding technician Autumn King. As the only women on a team of nearly 40 instructors and technicians, they share their career journeys, classroom experiences and what it means to mentor the next generation of manufacturing talent.

Through their stories, you’ll hear how ATDM’s fast-paced, 600-hour program equips students for life-changing careers in welding, metrology and more—and why representation matters in the skilled trades. This conversation highlights the impact of teaching, perseverance, and opportunity.

Welding instructor Makayla Baker, metrology instructor Holly Lyle and welding technician Autumn King

🎙️Topics Covered:

The August 2025 edition of IALR at a Glance is packed with exciting news and updates! Learn more about…

DANVILLE, Va. (July 31, 2025) – Accelerated Training in Defense Manufacturing (ATDM) recently celebrated its 1,000th program completer, highlighting the program’s continued success in building the defense workforce.

Glenn Claypool was recognized as the 1,000th program completer and joined fellow students in celebrating the cohort’s completion of the 16-week rigorous workforce training. Claypool discovered ATDM after completing a bachelor’s degree in business management and working in sales before deciding to pursue qualifications in non-destructive testing.

“ATDM has given me a second chance at having a fulfilling career that provides a true sense of purpose,” said Claypool. “It’s not just a job, it’s a path that has equipped me with skills that I’ll carry with me for the rest of my life.”

Created to support defense manufacturing initiatives across the United States and supply workers for the maritime industrial base, ATDM is well on its way toward its goal of 800-1,000 skilled tradespeople completing the program each year.

“Reaching 1,000 ATDM graduates bolsters a skilled workforce that our maritime industrial base needs urgently,” said Matt Sermon, direct reporting program manager of the Maritime Industrial Base Program. “ATDM graduates are contributing directly to building and sustaining our Fleet. As we scale this proven model nationwide, we’re helping our maritime industrial base develop the workforce needed to maintain maritime superiority for generations to come.”

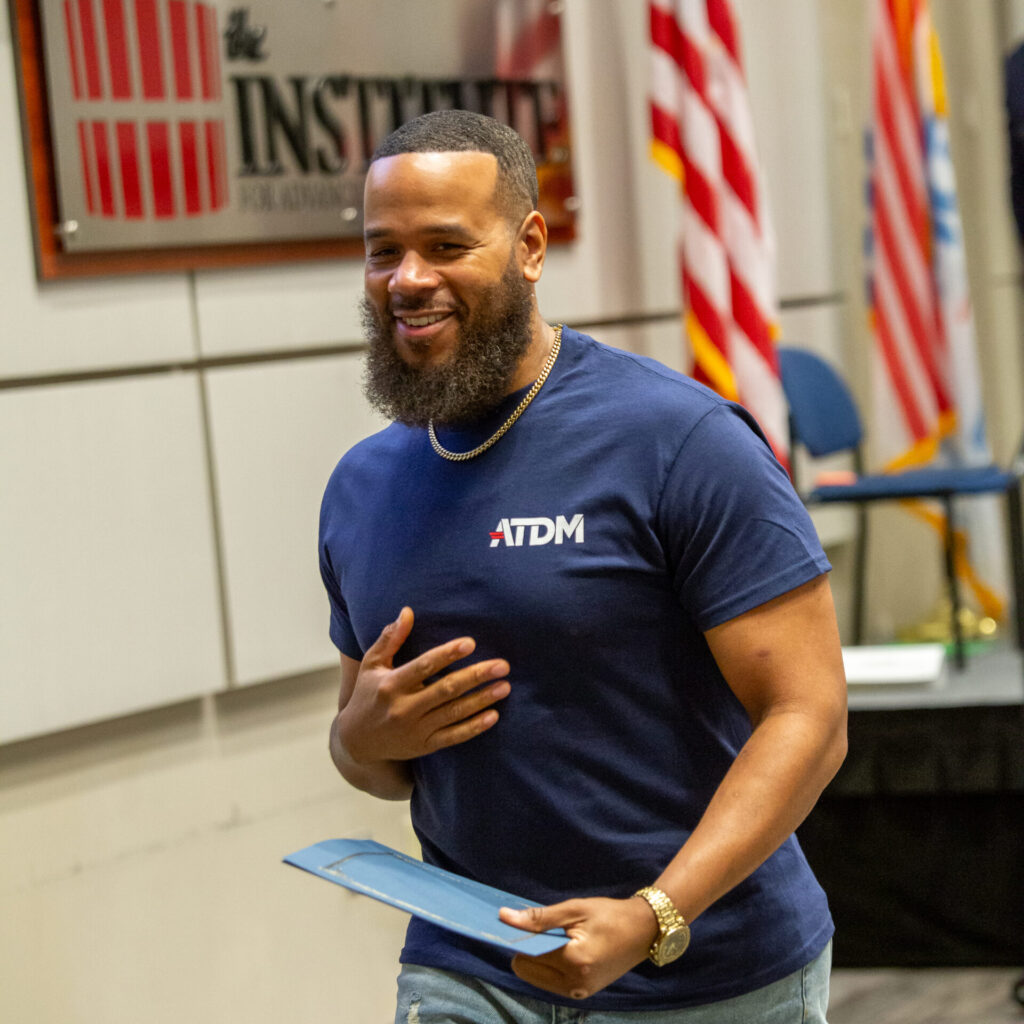

Will Kaisen, the student speaker for cohort 17, speaks during the ATDM Completion Ceremony.

Graduating students complete 600 hours of intensive, hands-on training over 16 weeks, earning certifications in one of five high-demand defense industry skilled trades. These are high-paying careers in additive manufacturing, CNC machining, non-destructive testing, quality control inspection (metrology) and welding.

“ATDM’s Maritime Training Center is a vital component of the work we do at IALR to support and pioneer new accelerated training methods that build the future workforce for defense, maritime and advanced manufacturing,” said Telly Tucker, president of the Institute for Advanced Learning and Research (IALR).

Congresswoman Jen Kiggans addressed the finishing cohort at their completion ceremony, highlighting her unique connection to ATDM’s purpose as a member of the House Armed Services Committee and the House Committee on Veterans’ Affairs, as well as being a Navy veteran herself and the wife of a Navy veteran.

Congresswoman Jen Kiggans speaks during the completion ceremony for the 17th cohort of the Accelerated Training in Defense Manufacturing (ATDM).

“This year the ATDM program is celebrating another major milestone, its 1,000th graduate, and that number represents the 1,000 men and women trained with the specialized skills needed to rebuild American manufacturing and support our defense industrial base, and that’s something to be proud of,” said Congresswoman Kiggans. “Graduates of this program are not just entering a workforce; you are stepping into a mission. Whether you’re heading to shipyards, maritime manufacturing facilities or defense plants across the country – your work will directly impact our national security.”

A distinguishing feature of the ATDM program is that students are prepared for the workforce beyond technical training. ATDM staff assist with resume development, interview preparation and direct employer connections, leading to an 85% employment rate for completers within a month of finishing the program. ATDM partners with more than 200 employers across the United States for job placement as well as job training, a strong indicator of the program’s success.

“ATDM has been a tremendous asset to our workforce development efforts. The program consistently turns out graduates who are not just technically capable, but ready to contribute from day one,” said Kristi Rowe, people director at Keel. “One of our recent hires has already made a strong impression in his welding role—bringing precision, confidence, and a solid grasp of quality standards. What really stands out is how well ATDM’s training aligns with the real-world demands of our work. It makes the transition from training to the job smooth and effective. We’re excited about the future and look forward to continuing this successful partnership.”

“I’ve met people from a wide range of backgrounds, different cultures, life experiences, education levels and career paths, but the one thing we all share is that we came to ATDM looking for new skills and opportunities,” said Claypool.

###

About ATDM

Accelerated Training in Defense Manufacturing (ATDM) was created to teach the skills needed to increase military equipment production in the United States. The program is located at the Institute for Advanced Learning and Research in Danville, Virginia. Students at ATDM are trained in the skills needed to repair, upfit and build submarines, and these skills are transferable to other defense industry companies. Students earn the qualifications needed to secure great-paying, in-demand defense industry jobs in these skilled trades: Additive Manufacturing, CNC Machining, Non-Destructive Testing, Quality Control Inspection (also known as Metrology) and Welding. For additional information, visit https://atdm.org/.

About IALR

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg, along with the cities of Martinsville and Danville.

The July 2025 edition of IALR at a Glance is packed with exciting news and updates! Learn more about…

The Institute for Advanced Learning and Research (IALR) today announced it has received a grant of software from Siemens Digital Industries Software.

The Institute for Advanced Learning and Research (IALR) today announced it has received a grant of software from Siemens Digital Industries Software.

The software, part of the Siemens Xcelerator portfolio, gives more than 1,000 students access to the same technology that companies around the world depend on to develop innovative products in a wide variety of industries, including automotive, aerospace, machinery, shipbuilding, high-tech electronics and many more. This software will be implemented in two primary programs:

“IALR is excited to have access to industry-leading software in our classrooms,” said Jason Wells, Executive Vice President of Manufacturing Advancement at IALR. “As the industry evolves, our graduates’ STEM skills must also evolve. This technology from Siemens Digital Industries Software will help ensure our students have the relevant digital skills necessary to succeed in Industry.”

Siemens Digital Industries Software is a leading global provider of engineering, manufacturing and electronics software.

The software provided by the Siemens Digital Industries Software academic program delivers technology for different skill levels. Graduates with training, experience and working knowledge of this type of software are highly recruited candidates for advanced technology jobs.

The software for IALR includes the following tools from Siemens Xcelerator:

“Bridging the gap between industry, academia and government is essential to building a sustainable talent pipeline equipped with the advanced skills required for the future of manufacturing,” said Melanie Spare, Director, Academic and Workforce Development. “This partnership exemplifies that mission—by aligning classroom training with the exact tools and technologies used by leading defense manufacturers, we’re not only accelerating workforce readiness, but also reinforcing critical Department of Defense initiatives. Through programs like ATDM and facilities like AM CoE, we’re creating a direct and seamless pathway from learning to doing, ensuring students are job-ready from day one.”

Many of IALR’s Manufacturing Advancement initiatives focus heavily on Department of Defense (DOD) requirements, and this software partnership significantly enhances that alignment. Students in the ATDM program will now train and operate using the same software as leading DOD suppliers, creating valuable continuity between classroom training and real-world defense manufacturing environments. Additionally, several of these Siemens products are already used within IALR’s Center for Manufacturing Advancement (CMA) and the U.S. Navy’s Additive Manufacturing Center of Excellence (AM CoE) due to their compliance with International Traffic in Arms Regulations (ITAR). This further strengthens the synergy between the AM CoE and ATDM, benefiting students by better preparing them for successful careers in defense manufacturing.

About IALR

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg along with the cities of Martinsville and Danville.

Note: A list of relevant Siemens trademarks can be found here.

In this episode of Inside IALR, host Caleb Ayers talks with Patrick Crowley and Ronald Green, recent graduates from the Accelerated Training in Defense Manufacturing (ATDM) program.

Listen in as they share:

Before ships, submarines and other vessels of the Maritime Industrial Base are deployed, thousands of skilled hands must shape raw material into critical components.

The Accelerated Training in Defense Manufacturing (ATDM) program in Danville, Va., ensures those hands are ready. It launches motivated individuals from no experience to defense-ready in four months through an accelerated program.

The program is located at and administered by the Institute for Advanced Learning and Research (IALR).

The results are clear: 82% graduate, and 75%-85% launch straight into jobs across the Maritime Industrial Base (MIB).

ATDM’s Six Core Goals

Built around 600 hours of immersive, hands-on learning, ATDM compresses years of traditional education into a straight-line employment pathway.

Four recent graduates who spoke on a panel at the 2025 ATDM & AM CoE Summit showed how the model works for participants and employers.

Abrams’s Story

Abrams’s Insights

Carter’s Story

Carter’s Insights

Debus’s Story

Debus’s Insights

Stricklin’s Story

Stricklin’s Insights

During this year’s ATDM & AM CoE Summit, Admiral James Kilby praised companies that hire ATDM alumni, noting they “aren’t just staying relevant—they’re getting ahead.”

ATDM’s scale-and-velocity approach is built for replication, and leaders across the Navy and industry say expanding the model nationwide is essential for sustaining a strong maritime industrial base.

Employers like HII, Keel, Austal USA and BWXT are already reaping the benefits—one motivated graduate at a time.

The Institute for Advanced Learning and Research (IALR) celebrated the graduation of the 16th cohort of the Accelerated Training in Defense Manufacturing (ATDM) program on May 6. The ceremony recognized 66 graduates who successfully completed rigorous training in specialized manufacturing fields critical to the defense industry and, more specifically, the Maritime Industrial Base (MIB).

This cohort’s graduates completed intensive, hands-on instruction across several specialized tracks, including CNC machining, metrology and welding. Each graduate completed over 600 hours of practical training, gaining industry-recognized credentials to prepare them for immediate entry into skilled roles within the MIB.

The ceremony’s keynote address was delivered by Rear Admiral Kent Whalen, who is retired from the U.S. Navy and now serves with The SPECTRUM Group.

“When you show up to your new employer, listen a lot, spend extra time being exposed to everything about the work and your skills as much as you can,” Whalen said. “Ask questions and read. Look for opportunities to upskill and seek additional training.”

Student speaker Ronald Green, a welding program graduate, shared personal insights and reflections on his collective experience.

“ATDM was an opportunity to not only learn valuable skills that provide a viable career path, but also to be able to contribute to something much greater than myself,” Green said. “The last four months here in Danville have been some of the most memorable times of my adult life. I’ve learned so much in a short time. I started out with classmates, who have since grown into my brothers and lifelong friends.”

“Today, we celebrate the achievements and hard work of our graduates who have completed the Accelerated Training in Defense Manufacturing (ATDM) program,” said Christa Reed, Interim Vice President of ATDM at IALR. “This milestone represents not only the knowledge and skills gained, but also the dedication and perseverance shown throughout the program. Congratulations to each of you for reaching this significant achievement, and congratulations to the ATDM team for their commitment and effort to ensure student success.”

Participants in the ATDM program benefit from comprehensive scholarships covering tuition and housing, ensuring a supportive environment that enables success for learners from diverse backgrounds, including transitioning veterans, industry newcomers and professionals shifting career paths.

The ATDM program, developed through collaboration with the Department of Defense, IALR, Danville Community College (DCC), Phillips Corporation and The SPECTRUM Group, directly responds to defense industry workforce needs. The program is on track to graduate over 800 students annually.

CNC Machining – 1st Shift

CNC Machining – 2nd Shift

Metrology – 1st Shift

Welding – 1st Shift

Welding – 2nd Shift

Welding – 3rd Shift

The Accelerated Training in Defense Manufacturing program provides focused, industry-driven training to equip participants with skills critical for defense manufacturing. This initiative is funded through the National Imperative for Industrial Skills by the Industrial Base Analysis and Sustainment Program Office within the Office of the Undersecretary of Defense for Acquisition and Sustainment.

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg and the cities of Martinsville and Danville.

The May 2025 edition of IALR at a Glance is packed with exciting news and updates! Learn more about…

In this episode of Inside IALR, we dive deep into the world of metrology, a crucial trade that plays a significant role in national defense manufacturing. The episode features Tony Almeida, Regional Sales Manager at Mitutoyo, and Jarrod Hankins, Metrology Instructor at IALR’s Accelerated Training in Defense Manufacturing (ATDM) program.

Metrology is the science of measurement. It ensures that parts are manufactured with incredible precision, often down to microns. Together, they highlight how metrology ensures that parts used in defense manufacturing, particularly in the Navy’s shipbuilding and repair operations, meet the highest standards of quality.

Highlights include:

Leaders from across the defense and manufacturing sectors came together in Danville, Virginia, for the fourth annual joint summit hosted by the Accelerated Training in Defense Manufacturing (ATDM) program and the U.S. Navy’s Additive Manufacturing Center of Excellence (AM CoE). Held at the Institute for Advanced Learning and Research (IALR), this year’s event, themed All Hands on Deck, focused on addressing workforce and manufacturing shortfalls in Navy shipbuilding and repair.

One of the summit highlights was a keynote address from Admiral James Kilby, USN, Vice Chief of Naval Operations, who spoke to the deep investment the Navy is making in workforce development and innovation as the pillars of our maritime strength.

“This Summit extends far beyond a two-day gathering—it’s strengthening America’s maritime industrial foundation,” said Matthew Sermon, direct reporting program manager for the Maritime Industrial Base. “With over 450 participants sharing insights and solutions, the ATDM Maritime Training Center is creating a pipeline of skilled workers, while the Additive Manufacturing Center of Excellence is revolutionizing how we produce critical components, reducing production timelines from years or months to weeks or days. Both are gamechangers….and together, these complementary initiatives address both the human talent and technological capabilities needed to build and sustain the fleet our nation requires.”

The summit highlighted the growth and momentum of the ATDM program. Earlier this year, the new 100,000-square-foot ATDM Maritime Training Center opened at the IALR campus, expanding the program’s capacity to train more students in its 16-week accelerated program. The ATDM Maritime Training Center provides the space needed for the program to graduate up to 1,000 students per year to meet industry demand, a target it is on track to achieve.

“At IALR, we’re pioneering new accelerated training methods while building the future workforce for defense and maritime manufacturing,” said Telly Tucker, president of IALR. “The new ATDM Maritime Training Center is a vital step in growing the talent pipeline, and by hosting the Navy’s Additive Manufacturing Center of Excellence on our campus, we’re integrating emerging technologies directly into the hands-on training process. This model ensures our graduates are equipped to meet challenges in shipbuilding and advanced manufacturing.”

Alongside workforce training, the co-located AM CoE continues to push the boundaries of additive manufacturing for Navy applications. The center is actively reducing production timelines for complex parts and exploring how advanced processes can support both new builds and fleet sustainment. The AM CoE is also providing connective tissue for ATDM students as they gain experience in additive manufacturing.

Throughout the summit, attendees heard from defense contractors, technical experts and government officials about the real-world impact of programs like ATDM and AM CoE. Representatives from major shipbuilders and supply chain companies discussed how the ability to hire ATDM graduates has shortened ramp-up times and helped meet production schedules.

The summit wrapped up with a clear sense of shared purpose and momentum. By combining accelerated training with cutting-edge innovation, ATDM and AM CoE are shaping a model for how public-private collaboration can secure the future of U.S. maritime power.

Accelerated Training in Defense Manufacturing (ATDM) was created to teach the skills needed to increase military equipment production in the United States. The program is located at the Institute for Advanced Learning and Research in Danville, Virginia. Students at ATDM are trained in the skills needed to repair, upfit and build submarines, and these skills are transferable to other defense industry companies. Students earn the skills needed to secure great-paying, in-demand defense industry jobs in these skilled trades: additive manufacturing, CNC machining, non-destructive testing, quality control inspection (also known as metrology) and welding.

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg along with the cities of Martinsville and Danville.

The April 2025 edition of IALR at a Glance is packed with exciting news and updates! Learn more about…

Inside the Institute for Advanced Learning and Research (IALR) Industry 4.0 Integration Lab, students from the Accelerated Training in Defense Manufacturing (ATDM) program and their instructor examine the robots, fixtures, work areas and CNC machines. They take detailed measurements and ask questions.

Butch Kendrick, IALR’s Director of Digital Manufacturing, has explained several “problems” he’s encountered in the lab. He asks these students to develop creative solutions using additive manufacturing to design and print different fixtures; the goal is to better support the Industry 4.0 Integration Lab’s mission of demonstrating and teaching Industry 4.0 concepts.

During the four-month program that prepares adult learners to work in the Maritime Industrial Base (MIB), ATDM students don’t just learn theory; they tackle real-world problems.

“Working on real projects while in the ATDM program significantly enhances the students’ readiness and confidence as they enter the workforce.” – Cheryl Terry, Director of ATDM Training and Technology, IALR

The Accelerated Training in Defense Manufacturing program at IALR is a hands-on training initiative designed to address the MIB workforce needs.

Currently, ATDM offers tracks in welding, additive manufacturing, CNC machining, quality control inspection (metrology) and non-destructive testing (NDT). Students benefit from tuition-free training, supportive services and guaranteed opportunities to earn industry-recognized qualifications.

ATDM’s emphasis on real-world, hands-on learning ensures that students gain practical skills directly applicable to manufacturing challenges.

“We get so much more buy-in from our students when they work on real-world situations. They get more gratification from fixing problems than just doing their homework.” – Tim Holland, ATDM Additive Manufacturing Instructor, IALR

To date, every cohort of additive manufacturing students has worked on a project in the Industry 4.0 Integration Lab. One of the first cohorts actually 3D printed the head of Rosie, one of the lab robots. The robot was designed to look like Bender from Futurama and eventually got the name Rosie from a Facebook naming poll.

Aaron Jacob Garcia with Rosie

“I make sure that the students understand the purpose of what they’re doing and how it all connects,” Kendrick said. “Once we do the initial session with them, the lab is open to them coming back and taking measurements and doing whatever they need to do.”

This cohort tackled four projects, including refining an existing fixture to ensure better robotic interaction and stability. Students fully managed their designs, from taking precise measurements to ensuring the fixture would securely interface with multiple table configurations.

“There is a problem, and they have to figure out how to fix it, but there’s no instruction list on how to do it,” Holland said.

Recent graduate Aaron Jacob Garcia said the experience taught him about the potential of additive manufacturing, the need for detailed, reliable measurements and the importance of understanding the end use.

“I learned that sometimes you have to make changes to make a part work for what it will be used for,” he said.

Allowing additive manufacturing students the opportunity to contribute to the Industry 4.0 Integration Lab is mutually beneficial.

“I think it’s a great opportunity for students to come out of the classroom into a real-life situation that isn’t too high pressure,” said Kendrick. “It gives them a chance to take what they’ve learned, mix it with their imagination and see what they can come up with.”

The Industry 4.0 Integration Lab provides an autonomous manufacturing environment featuring advanced robotics, automation and digital technologies. This focus makes it an ideal platform for training future manufacturing professionals, demonstrating real-world Industry 4.0 principles, and creating tangible outcomes for students and industry partners.

The Lab is housed within the Center for Manufacturing Advancement (CMA) on the IALR campus. The CMA equips manufacturers to be globally competitive by supporting the seamless integration of emerging technology into manufacturing processes.

“Allowing students to participate in these types of real-world, hands-on projects is mutually beneficial for everybody involved and furthers the mission of both the ATDM program and the CMA.” – Jason Wells, Executive Vice President, Manufacturing Advancement, IALR

The Accelerated Training in Defense Manufacturing (ATDM) program celebrated its 15th and largest graduating cohort with a ceremony held at the Institute for Advanced Learning and Research (IALR) on March 14. The event honored 98 graduates who completed four months of intensive manufacturing training on the IALR campus in Additive Manufacturing, CNC Machining, Non-destructive Testing and Welding.

The ceremony featured a keynote address by Captain James P. “JIP” Mosman, Commander of the Norfolk Naval Shipyard, and student remarks by Jonathan Rada, who completed the Additive Manufacturing program.

“The Maritime Industrial Base is the foundation of both our national security and global supply chain… Whether you are ensuring the structural integrity of a vessel, contributing to cutting edge innovation or supporting mission critical operations, you are playing a role in something much larger than yourself. You are joining a workforce in a legacy of service, resilience and innovation.” – Captain James P. “JIP” Mosman, Commander of the Norfolk Naval Shipyard

“I’ve learned invaluable skills, made lifelong friends and found a sense of a sense of purpose that has eluded me for years. It’s never too late to reinvent yourself, take risks, and when opportunity knocks, show up.” – Jonathan Rada, Additive Manufacturing Graduate, incoming CNC Machinist with General Dynamics

The ATDM program equips adult learners with critical skills and credentials to succeed in careers within the maritime industrial base (MIB), which produces and maintains essential parts and equipment for ships and submarines. ATDM participants receive full scholarships covering tuition and housing.

The curriculum is guided by direct input from industry partners, ensuring graduates meet the immediate workforce needs of defense manufacturers. Throughout their training, students complete 600 hours of hands-on instruction and earn multiple industry-recognized credentials. Many participants secure employment offers even before graduation.

Participants in the ATDM program come from across the United States, representing diverse backgrounds including veterans transitioning from military service, professionals changing industries and individuals new to manufacturing. With the Navy’s National Training Center that opened earlier in 2025, the program is set to train between 800 and 1,000 students annually.

Additive Manufacturing: Vincent Corbo, Joshua Davis, Talbert Dunn, Aaron Garcia, David Goree, Jim-Nicholas James, Michael McFadden, Lisa Parrotta, Alexander Peabody, Jonathan Rada, Sean Verrando

CNC Machining (1st Shift): Natasha Barnes, David Heil, Kevin Holodak, William Perry, Caleb Polasik, Rodrigo Van Rooy, James Wilson, Kamry Wilson

CNC Machining (2nd Shift): Nahid Bakhtari, Isaiah Booker, GianCarlo De La Paz, Majeed Ebrahimi, Chrday Fields, Julian Litlv, Daniel Pearce, Darcy Souza, Desmond Steele, Dustin Tatro, Xavier Thomas, Mace Tyrsdottir, Christopher Tucker

CNC Machining (3rd Shift): Carlos Bueno, William Cadwalader, Roberto Corona-Rodriguez, Claudio Gutierrez, Joshua Hjelle, Abuobaida Elamin, Padraic Noonan, Ryan Sanders, John Soltis, James Tyson

Non-destructive Testing: Edward Bakshis, Nathaniel Brown, Dustin Byrum, Zachery Carmean, DeAndre DeScott, Aquiles Guedes Rapassi, Nicole Hillstrom, Shawn Kizzee, Brandon Lay, Julian Littman-van Hoek, Trinidad Magdaleno, Kalief Manuel, Herbert McClain, Owen McNeill, Jessica Roy, Nicholas Sacharko, Zachary Snyder, Anna Stone, Mathew Walter, Aaron Watt

Welding (1st Shift): Ian Barba, Nicholas Barron, Jennifer Baumgartner, Thomas Cluchey, Michael Jenrich, Spencer Long, Anthony Mazzucca, Corey McWhorter, Anna Mikulec, Brandon Robinson

Welding (2nd Shift): Shonteniece Brown, Faith Chandler, Bethany Fairchild, Aiden Ferrell, Candace Green, Gracen Haught, J Nicholas Leppo, Peyton Phillips, Shaboo Reid, Santiago Rizo Lomeli, Ian Tamez, Rolando Velasco, Devin Walker

Welding (3rd Shift): Valdemarr Davis, Clayton Dierks, Emanuel Flores, Isaiah Forbes, Angel Gomez, Clay Hopper, Damien Jamison, James Kelly, Marquise Parker, Tyreek Robb, Britton Shover, Josue Sinico Velazquez, Carlos Walker

Accelerated Training in Defense Manufacturing was developed as a public-private consortium between the Department of Defense, IALR, Danville Community College (DCC), Phillips Corporation, and The SPECTRUM Group in consultation with the defense industry. IALR leads the multi-year pilot project funded by the National Imperative for Industrial Skills initiative of the Industrial Base Analysis and Sustainment Program Office in the Office of the Undersecretary of Defense for Acquisition and Sustainment.

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg, along with the cities of Martinsville and Danville.

Effective learning blends theoretical instruction with real-world application. At the Institute for Advanced Learning and Research (IALR), hands-on training is a core principle across diverse programs.

“Theory is important, and it has value. However, my years working in and with educators has taught me that most learners are visual kinesthetic learners, and the most impactful learning tends to be hands-on learning.” – Telly Tucker, IALR President

This approach equips participants with practical skills and boosts their confidence in real job environments. Whether middle school students or seasoned adults, participants walk away with experiences they can immediately apply.

The Great Opportunities in Technology and Engineering Careers (GO TEC®) program exposes middle school students to the emerging technologies shaping tomorrow’s industries. Students learn about and, more importantly, get to practice with virtual reality welding tools, desktop CNC mills, different types of robots and much more, offering a direct glimpse into in-demand careers.

“Middle school is the perfect time to spark a lasting interest in STEM. Getting to touch and try these business-relevant technologies shows that advanced concepts and careers are within reach.” – Julie Brown, Ph.D., Vice President of Advanced Learning

Dual-enrollment students in the Academy for Engineering and Technology (AET)—a collaboration with Danville Community College and the local school divisions—learn concepts in the classroom and apply them immediately. This balance of theory and application strengthens their problem-solving abilities and prepares them for modern challenges.

“We’ve seen impressive results when students can test what they learn right away,” Dr. Brown says. “That combination pushes them to think critically and perform with confidence.”

IALR also houses students in the Piedmont Governor’s School for Mathematics, Science, and Technology. Every year, seniors in this program participate in a senior research project, some seeking support from IALR’s Applied Research division.

Accelerated Training in Defense Manufacturing (ATDM) equips adult learners with the skills needed to work with Navy suppliers in the Maritime Industrial Base. In just four months, participants build foundational knowledge and participate in hundreds of hours of hands-on practice with actual machinery.

“ATDM bridges the gap between classroom insights and real-world shop floors. Graduates leave ready to excel in high-demand defense manufacturing roles.” – Jason Wells, Executive Vice President of Manufacturing Advancement

In the Integrated Machining Technology (IMT) program, developed with Danville Community College, students face the pressure of meeting manufacturing quotas and deadlines. This setup mirrors the intensity of a true manufacturing environment.

“It’s a simulated manufacturing flow cell,” Wells said. “We put these students in a position to practice how all the pieces they’ve learned come together.”

IALR also hosts shorter programs on topics like Fanuc robotics, precision machining for instructors and industrial fermentation. These workshops blend conceptual lessons with live experimentation in a condensed timeframe.

“Our recent industrial fermentation workshop revealed how hands-on demos deepen understanding. When participants participate in the process, they gain a better understanding.” – Scott Lowman, Ph.D., Vice President of Applied Research, IALR

The journey does not end with a certificate or first job. Through various computer training workshops and the Wonder Community of Lifelong Learning, people can refresh their skills or discover new interests at any stage.

IALR’s commitment to lifelong learning and service learning opens pathways for professionals and hobbyists alike.

From virtual reality welding in GO TEC® to advanced precision machining in IMT, practical immersion helps learners of all ages gain a deeper understanding. Hands-on learning is particularly beneficial in the STEM fields, as shown by many different studies, including from Purdue University and the Proceedings of the National Academy of Sciences of the United States of America. With IALR’s goal of expanding STEM Capacity, this focus on hands-on, practical learning is what drives success.

“Practical experiences let learners see immediate results,” Tucker says. “When students engage directly, they become more prepared for today’s job market.”

Browse Educational Programs and Services

This episode features Daniel Hyler and Tim Holland—two graduates turned additive manufacturing instructors with the Accelerated Training in Defense Manufacturing (ATDM) program. Hear them discuss lessons they picked up along the way, plus real-world applications of additive manufacturing in today’s job market.

Listen in as they discuss:

In this episode, Senior Facilities Manager Stewart East and Assistant Director of Advanced Training and Operations Wesley Cifers explain:

Preparation: Months of logistical strategizing for a multi-phase relocation

Execution: Coordinating staff, resources, and external partners over the holidays

Outcome: A smoother transition to the Navy’s ATDM Maritime Training Center, where the Accelerated Training and Defense Manufacturing (ATDM) program now has a permanent home

Episode highlights include: